Introduction to Zero Turn Hydrostatic Transmission

The zero turn hydrostatic transmission has revolutionized the lawn care industry, offering unmatched maneuverability, faster mowing speeds, and precision cuts. Unlike traditional gear-driven systems, the zero turn hydrostatic transmission provides infinitely variable speed control and the ability to turn within its own footprint, making it an essential component of modern zero turn radius (ZTR) mowers.

At the heart of every high-performance zero turn mower lies a sophisticated zero turn hydrostatic transmission system. This technology has become the gold standard for both residential and commercial lawn care equipment, delivering smooth operation, reduced operator fatigue, and increased productivity. Understanding the inner workings of a zero turn hydrostatic transmission is crucial for anyone looking to maximize the performance and lifespan of their ZTR mower.

The zero turn hydrostatic transmission operates on the principle of fluid dynamics, using hydraulic pressure to transfer power from the engine to the wheels. This system eliminates the need for traditional gears, clutches, and mechanical linkages, resulting in a more efficient and low-maintenance drive system. Whether you're a professional landscaper or a homeowner with a large property, the benefits of a zero turn hydrostatic transmission are undeniable.

Key Benefits of Zero Turn Hydrostatic Transmission:

- Infinite Speed Control: Adjust speed seamlessly without shifting gears

- Zero Turning Radius: Maneuver in tight spaces and around obstacles with ease

- Smooth Operation: Eliminate jerky starts and stops common with gear-driven systems

- Reduced Maintenance: Fewer moving parts mean less wear and tear

- Increased Productivity: Cover more ground in less time with higher operating speeds

As the demand for more efficient and productive lawn care equipment continues to grow, manufacturers are constantly innovating to improve the performance and reliability of zero turn hydrostatic transmission systems. From advanced fluid technology to precision engineering, the latest zero turn hydrostatic transmission systems offer unprecedented levels of efficiency and durability.

Zero Turn Hydrostatic Transmission at a Glance

Efficiency

Up to 85% efficient in optimal conditions

Maintenance

Moderate maintenance requirements

Cost

Higher initial cost, lower long-term cost

Lifespan

500-1,500 hours with proper maintenance

Did You Know?

The first zero turn hydrostatic transmission systems were introduced in the 1960s, but it wasn't until the 1990s that they became widely adopted in the lawn care industry.

How Zero Turn Hydrostatic Transmission Works

The zero turn hydrostatic transmission operates on the fundamental principle of fluid power, converting mechanical energy into hydraulic energy and back into mechanical energy to drive the wheels. This closed-loop system consists of two main components: a variable displacement pump and a fixed displacement motor.

In a typical zero turn hydrostatic transmission system, hydraulic lines connect the variable-displacement pump to the fixed-displacement motor that powers one of the rear wheels. When the operator moves the control lever forward, it increases the pump displacement, which in turn increases the flow of hydraulic fluid to the motor, causing the wheel to turn faster. The beauty of this system is its infinite variability—meaning the engine can be running at a constant speed (typically 3,600 RPM), but the wheel speed depends entirely on how far the operator pushes the control lever.

A key advantage of the zero turn hydrostatic transmission is its ability to independently control each rear wheel. By having separate hydrostatic transmissions for the left and right wheels, the mower can achieve a true zero turning radius. When one wheel is driven forward and the other backward at the same speed, the mower spins around its center axis, making it incredibly maneuverable in tight spaces.

The Hydrostatic Loop

The closed-loop hydraulic circuit, or hydrostatic loop, is the heart of the zero turn hydrostatic transmission. This loop consists of high-pressure hydraulic lines that connect the pump outlet to the motor inlet and the motor outlet back to the pump inlet. This design allows for efficient power transfer and precise control over the motor speed and direction.

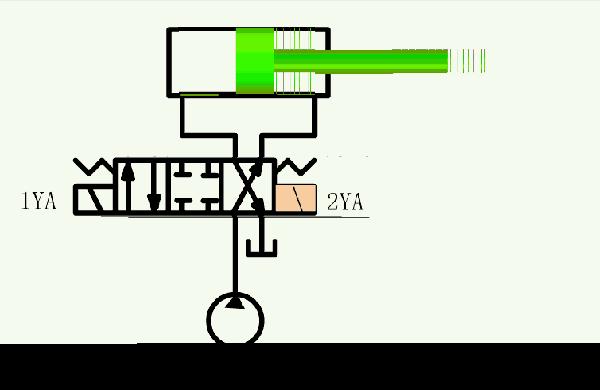

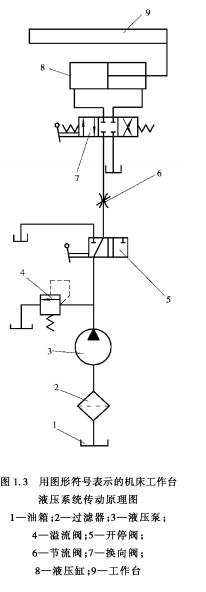

Zero Turn Hydrostatic Transmission Animation

Schematic representation of a basic hydrostatic transmission system

Key Operating Principles

Fluid Displacement

The variable displacement pump changes the amount of fluid it moves per revolution, which directly controls the speed of the hydraulic motor. This displacement is controlled by the operator via the control levers.

Pressure Compensation

Modern zero turn hydrostatic transmission systems include pressure compensating valves that maintain consistent performance even under varying loads, ensuring smooth operation in all conditions.

Charge Pump System

A separate charge pump maintains proper fluid levels in the hydrostatic loop, compensating for any leakage and ensuring consistent performance. This pump also helps cool the hydraulic fluid.

权威文献引用

"The hydrostatic transmission (HST) systems have been widely adopted in off-road vehicles for providing large power density and continuous variable control, yet using relatively low efficiency hydraulic components. The operating parameters of the pump and the motor in a hydrostatic system are critical to the overall performance of the system."

Components of Zero Turn Hydrostatic Transmission

Main Components

-

Variable Displacement Pump: Converts mechanical energy from the engine into hydraulic energy by pressurizing fluid.

-

Fixed Displacement Motor: Converts hydraulic energy back into mechanical energy to drive the wheels.

-

Hydraulic Fluid: Transfers energy within the system while lubricating and cooling components.

-

Control Valves: Regulate fluid flow and pressure within the system.

-

Hydraulic Lines: Connect components and carry hydraulic fluid throughout the system.

Auxiliary Components

-

Charge Pump: Maintains fluid pressure in the system and compensates for leakage.

-

Reservoir: Stores hydraulic fluid and helps dissipate heat.

-

Filter: Removes contaminants from the hydraulic fluid to protect system components.

-

Cooler: Regulates fluid temperature to prevent overheating.

-

Relief Valve: Protects the system from excessive pressure by releasing fluid when pressure exceeds safe limits.

Component Functionality and Design

Variable Displacement Pump

The variable displacement pump is the heart of the zero turn hydrostatic transmission system. It consists of a series of rotating pistons that ride against a swash plate connected to the control handle. As the swash plate angle changes, the pistons stroke length varies, changing the amount of fluid displaced per revolution.

This design allows the pump to deliver fluid at varying flow rates, which directly controls the speed of the hydraulic motor. In zero turn mowers, variable displacement piston pumps are the most common type due to their efficiency and ability to handle high pressures.

Hydraulic Motor

Most zero turn hydrostatic transmission systems use a gerotor motor to convert hydraulic energy back into mechanical energy. The gerotor motor uses a valve body to pressurize fluid between a rotor and stator, causing the rotor to orbit around the stator.

As the rotor orbits clockwise, it rotates counterclockwise at a much lower speed. The rotor is splined to the output shaft, which drives the mower wheels. This design provides high torque output with compact dimensions, making it ideal for zero turn mower applications.

Hydraulic Fluid Requirements

The zero turn hydrostatic transmission places specific demands on hydraulic fluid. The gerotor motor in particular generates increased sliding forces on the splines, requiring anti-wear additives like zinc and phosphorus to form a wear-resistant barrier on parts.

These transmissions operate with extremely tight clearances under high pressure, which can mechanically shear lesser-quality oils, reducing viscosity and changing the behavior of the machine. High-quality synthetic fluids are recommended for optimal performance and longevity of the zero turn hydrostatic transmission system.

Zero Turn Hydrostatic Transmission Component Comparison

| Component | Function | Common Issues | Maintenance Tips |

|---|---|---|---|

| Variable Displacement Pump | Converts mechanical energy to hydraulic energy | Internal leakage, swash plate wear | Regular fluid changes, use high-quality fluid |

| Hydraulic Motor | Converts hydraulic energy to mechanical energy | Rotor/stator wear, spline damage | Monitor fluid cleanliness, avoid overloading |

| Hydraulic Fluid | Energy transfer, lubrication, cooling | Contamination, oxidation, viscosity loss | Change at recommended intervals, use OEM-specified fluid |

| Control Valves | Regulate fluid flow and pressure | Valve sticking, internal leakage | Regular system flushing, avoid contamination |

| Hydraulic Lines | Connect components and carry fluid | Leaks, abrasion damage | Inspect regularly, replace damaged lines immediately |

Performance of Zero Turn Hydrostatic Transmission

Efficiency Analysis

The efficiency of a zero turn hydrostatic transmission is a critical factor in its performance and operating costs. While a discrete-gear transmission typically has an efficiency of 95% or greater, a well-designed zero turn hydrostatic transmission can achieve efficiencies of around 80-85% under optimal conditions.

Several factors influence the efficiency of a zero turn hydrostatic transmission:

- Fluid viscosity and temperature

- System pressure and flow rate

- Component design and manufacturing quality

- Operating speed and load conditions

- Maintenance practices

Efficiency vs. Productivity

While gear-driven systems offer higher mechanical efficiency, the zero turn hydrostatic transmission provides significant productivity gains through improved maneuverability and speed control. For most commercial applications, these productivity gains offset the slightly lower efficiency, resulting in lower overall operating costs.

Performance Metrics

Max Speed

7-13 mph

Depending on model and application

Torque Output

Up to 350 Nm

At the axle shaft

Pressure Rating

3,000-5,000 psi

System operating pressure

Flow Rate

10-30 gpm

Depending on pump size

Zero Turn Hydrostatic Transmission Comparison

| Model | Max Speed | Torque | Efficiency | Application |

|---|---|---|---|---|

| Hydro-Gear EZT | 7 mph | 180 Nm | 80% | Residential |

| Hydro-Gear ZT-2800 | 7.5 mph | 220 Nm | 82% | Residential/Commercial |

| Hydro-Gear ZT-3100 | 8 mph | 250 Nm | 83% | Commercial |

| Hydro-Gear ZT-3400 | 9 mph | 290 Nm | 84% | Heavy-Duty Commercial |

| Tuff Torq TZ-350 | 8 mph | 350 Nm | 81% | Residential/Commercial |

| Tuff Torq TZT7-M | 9 mph | 310 Nm | 82% | Commercial |

Performance Enhancements

Manufacturers are constantly innovating to improve the performance of zero turn hydrostatic transmission systems. Some of the latest advancements include:

Advanced Fluid Technology

Synthetic hydraulic fluids with improved shear stability and thermal resistance, such as AMSOIL's synthetic hydrostatic transmission fluid, maintain viscosity better in severe service conditions.

Integrated Design

Integrated hydrostatic transaxles reduce the number of parts from 72 to just 2, improving efficiency by up to 10% compared to competitive offerings (Parker Hannifin Corporation).

Electronic Controls

Advanced control systems, such as fuzzy sliding mode control, improve both the control performance and energy efficiency of zero turn hydrostatic transmission systems.

Maintenance of Zero Turn Hydrostatic Transmission

Maintenance Schedule

Daily

Check fluid level and condition, inspect for leaks

Every 50 Hours

Clean hydraulic cooler and filter

Every 100 Hours

Change hydraulic fluid and filter

Every 200 Hours

Inspect hoses and connections, check belt tension

Every 500 Hours

Complete system inspection, check for wear

Common Issues and Troubleshooting

Low Hydraulic Oil

A low oil level may not provide sufficient lubrication and cause the mower to feel weak and move slowly on one side.

Solution: Check oil level and add fresh oil if needed. Inspect for leaks if fluid level is low.

Contaminated Hydraulic Fluid

Old or contaminated fluid can cause poor performance, overheating, and increased wear on components.

Solution: Drain contaminated oil and replace with fresh, high-quality hydraulic fluid recommended by the manufacturer.

Air in the Hydraulic System

Air in the system can cause spongy operation, cavitation, and reduced performance.

Solution: Purge the system according to the manufacturer's instructions to remove air bubbles.

Worn Drive Belt

A worn or damaged drive belt can reduce power transfer to the hydrostatic pump.

Solution: Inspect the belt for cracks, fraying, or excessive wear and replace if necessary.

Overheating

Excessive heat can cause fluid degradation and component damage.

Solution: Check cooling system, clean cooler fins, ensure proper fluid level and quality.

Maintenance Best Practices

-

Use the Correct Fluid: Always use the hydraulic fluid recommended by the manufacturer. Using the wrong fluid can cause premature wear and system failure.

-

Keep the System Clean: Dirt and contaminants are the primary cause of hydrostatic transmission failure. Always clean around filler caps before opening the system.

-

Check for Leaks Regularly: Even small leaks can lead to significant problems over time. Inspect hoses, connections, and seals regularly for signs of leakage.

-

Follow Proper Warm-Up Procedures: Allow the hydraulic fluid to reach operating temperature before putting the system under heavy load.

-

Store Properly: When storing the mower for extended periods, follow the manufacturer's recommendations for fluid maintenance and system protection.

Fluid Selection Guide

Choosing the right hydraulic fluid is crucial for the performance and longevity of your zero turn hydrostatic transmission. The fluid must provide proper lubrication, corrosion protection, and thermal stability while maintaining the correct viscosity under operating conditions.

Fluid Types

-

Mineral-Based Hydraulic Oils: Economical option suitable for moderate operating conditions.

-

Synthetic Hydraulic Oils: Offer superior performance in extreme temperatures and heavy-duty applications.

-

Biodegradable Hydraulic Fluids: Environmentally friendly option for sensitive areas.

-

Multi-Viscosity Hydraulic Oils: Provide good performance across a wide temperature range.

Fluid Specifications

-

Viscosity: Typically ISO 32, 46, or 68 grades. Check manufacturer recommendations.

-

Viscosity Index: Higher values indicate better viscosity stability across temperatures.

-

Pour Point: Indicates the lowest temperature at which the fluid will flow.

-

Total Acid Number (TAN): Indicates the fluid's ability to resist oxidation.

Expert Tip

When changing hydraulic fluid, always replace the filter at the same time. Even a small amount of contamination can quickly degrade the performance of new fluid. Also, be sure to properly dispose of used hydraulic fluid according to local regulations.

Frequently Asked Questions

Glossary of Terms

Key Terms

- Cavitation

- The formation and collapse of air bubbles in hydraulic fluid, which can cause damage to components and reduce efficiency.

- Charge Pump

- A small auxiliary pump that maintains fluid pressure in the hydrostatic system and compensates for leakage.

- Displacement

- The volume of fluid moved by a pump or motor in one revolution.

- Fixed Displacement Motor

- A hydraulic motor that produces a constant speed for a given flow rate.

- Gerotor Motor

- A type of hydraulic motor that uses an inner rotor and outer stator to convert fluid pressure into mechanical rotation.

- Hydrostatic Loop

- The closed hydraulic circuit that connects the pump and motor in a hydrostatic transmission system.

More Terms

- Hydraulic Fluid

- The specialized fluid used in hydraulic systems to transfer energy, lubricate components, and dissipate heat.

- Pressure Relief Valve

- A safety valve that protects the hydraulic system from excessive pressure by releasing fluid when pressure exceeds a predetermined level.

- Swash Plate

- A component in variable displacement pumps that controls the amount of fluid displaced per revolution by changing the angle of the plate.

- Variable Displacement Pump

- A hydraulic pump that can vary the amount of fluid it displaces per revolution, allowing for variable flow rates and pressure.

- Viscosity

- A measure of a fluid's resistance to flow, which affects the performance of hydraulic systems.

- Zero Turn Radius

- The ability of a vehicle to turn around within its own footprint, made possible by independent control of each drive wheel.

Ready to Learn More About Zero Turn Hydrostatic Transmission?

Discover how the latest advancements in zero turn hydrostatic transmission technology can improve your lawn care efficiency and reduce maintenance costs.

Learn more