Table of Contents

1. Development of Hydraulic Transmission

The history of hydraulic transmissions spans several centuries, with significant advancements accelerating during the Industrial Revolution and continuing to the present day. The fundamental principles of hydraulics were first recognized by ancient civilizations, but the practical application of these principles in mechanical systems is a more modern development.

The foundations of modern hydraulics can be traced back to the 17th century when Blaise Pascal formulated Pascal's Law, which states that pressure exerted anywhere in a confined incompressible fluid is transmitted equally in all directions throughout the fluid. This principle became the cornerstone of hydraulic transmission systems.

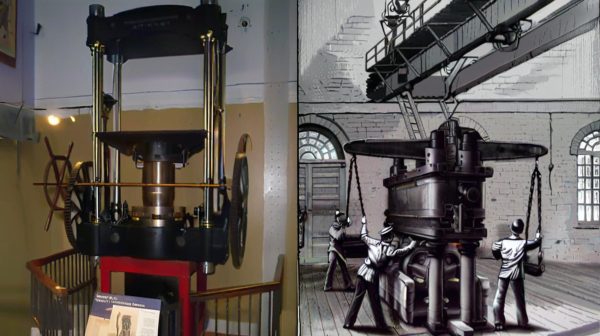

In the 18th century, Joseph Bramah developed the hydraulic press based on Pascal's principles, creating one of the first practical applications of hydraulic power. Bramah's invention demonstrated the enormous force-multiplying capabilities of hydraulic systems, laying the groundwork for future hydraulic transmission technologies.

The 19th century saw the first applications of hydraulic systems in industrial settings. Hydraulic power was used in factory machinery, with water as the primary working fluid. However, these early systems were limited by leakage issues and the corrosive properties of water.

Significant advancements occurred in the early 20th century with the development of suitable hydraulic fluids and improved sealing technologies. This period saw the introduction of hydraulic systems in automotive applications, particularly in braking systems. The invention of the hydraulic pump allowed for more efficient fluid pressurization, expanding the possibilities for hydraulic transmission.

During World War II, the demand for powerful, compact, and reliable power transmission systems led to rapid advancements in hydraulic technology. Military applications such as aircraft landing gear, tank steering systems, and artillery positioning mechanisms drove innovations in hydraulic transmission design and performance.

In the post-war period, hydraulic transmission technology found widespread adoption in industrial machinery, construction equipment, and agricultural vehicles. The 1960s and 1970s saw the integration of electronic controls with hydraulic systems, enabling more precise operation and automation.

The late 20th century brought advancements in materials science, leading to more durable components and improved efficiency. Computer-aided design (CAD) allowed for more sophisticated system designs, optimizing performance and reducing energy losses in hydraulic transmission systems.

Today, hydraulic transmission continues to evolve with the integration of smart technologies, sensors, and advanced control systems. Modern hydraulic systems are more efficient, environmentally friendly, and versatile than ever before, finding applications in industries ranging from manufacturing to renewable energy.

The ongoing development of hydraulic transmission technology focuses on improving energy efficiency, reducing environmental impact, and enhancing system intelligence through digitalization and the Industrial Internet of Things (IIoT).

Working Principles

How does a hydrostatic transmission work?Hydraulic transmission systems operate based on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to all portions of the fluid and the walls of its container. This principle enables the transfer of force from one point to another through an incompressible fluid, typically hydraulic oil.

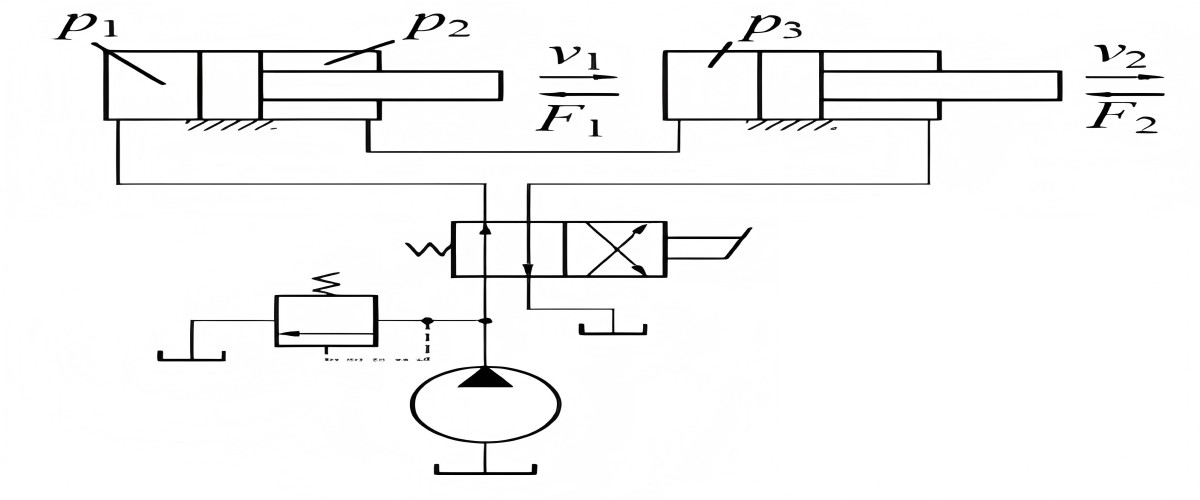

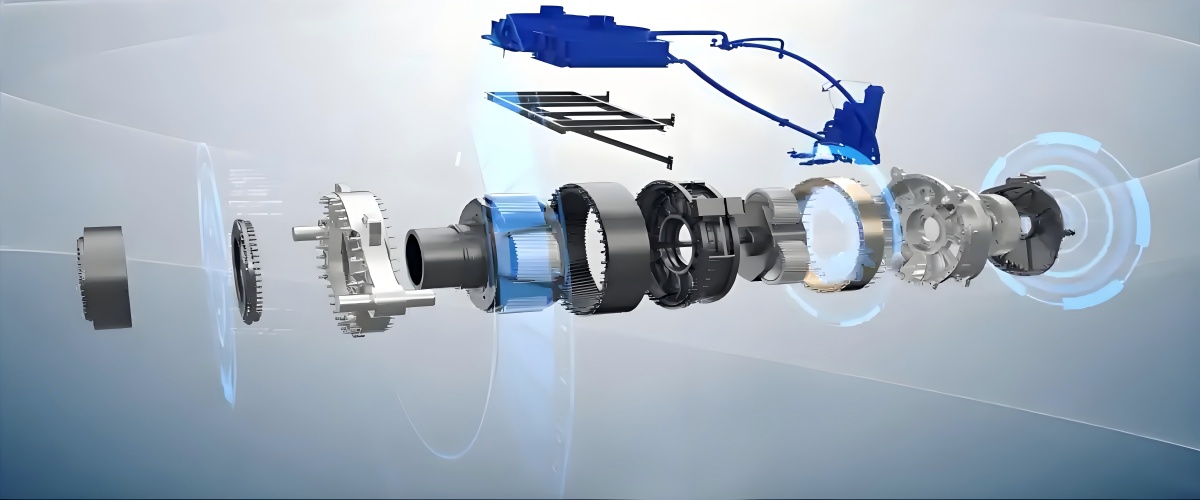

The basic operation involves converting mechanical energy into hydraulic energy (pressure energy) at one point, transmitting this energy through a fluid, and then converting it back to mechanical energy at another point. This energy conversion and transmission process allows for flexible power distribution in various mechanical systems.

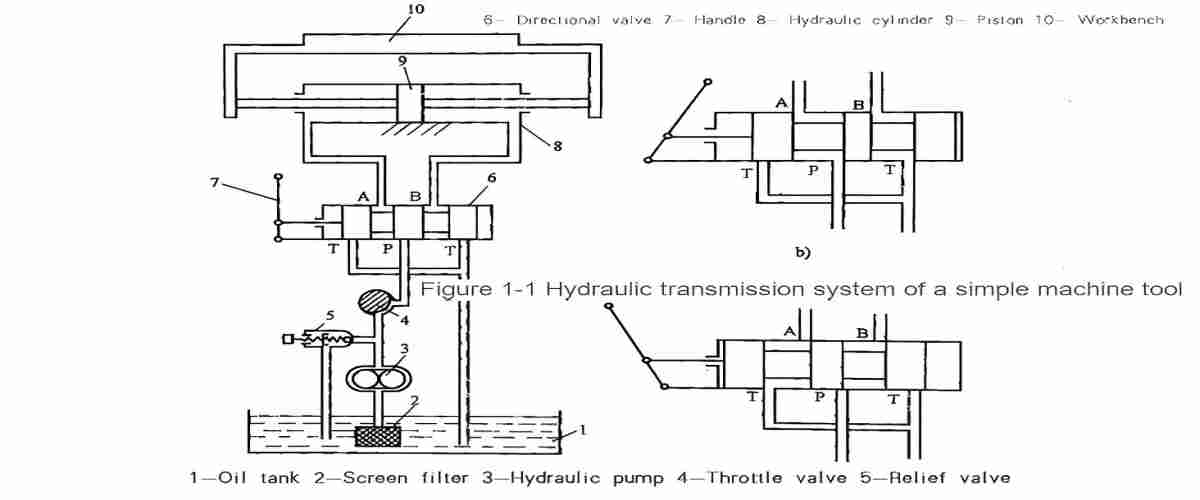

In a typical hydraulic transmission system, a pump creates flow and pressure in the hydraulic fluid. This pressurized fluid is then directed through valves to actuators (cylinders or motors), which convert the hydraulic energy back into mechanical motion (linear or rotational). The ability to control the pressure, flow rate, and direction of the fluid allows for precise control of the actuators.

Key Components

Power Source

The power source, typically an electric motor or internal combustion engine, provides the mechanical energy needed to drive the hydraulic pump. The selection of the power source depends on the specific application requirements of the hydraulic transmission system.

Hydraulic Pump

The hydraulic pump converts mechanical energy into hydraulic energy by creating flow and pressure in the hydraulic fluid. Common types include gear pumps, vane pumps, piston pumps, and screw pumps, each offering different performance characteristics for various transmission applications.

Control Valves

Control valves regulate the pressure, flow rate, and direction of hydraulic fluid in the system. They include directional control valves, pressure control valves, flow control valves, and servo valves, which are essential for precise operation of the hydraulic transmission.

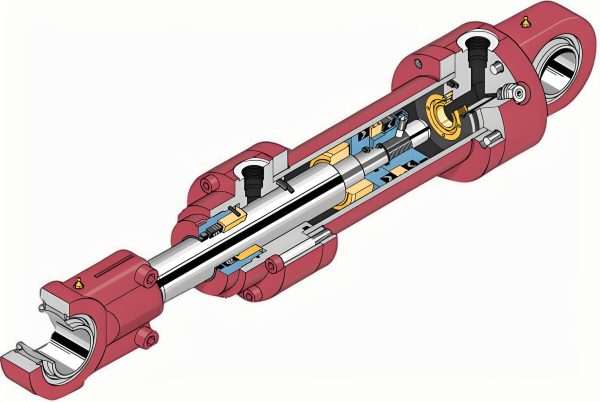

Hydraulic Actuators

Actuators convert hydraulic energy back into mechanical energy. Linear actuators (hydraulic cylinders) produce straight-line motion, while rotary actuators (hydraulic motors) produce rotational motion. These components are the "working ends" of the hydraulic transmission system.

Fluid Conductors

These include pipes, hoses, and fittings that transport hydraulic fluid between components. Proper sizing and selection of fluid conductors are critical for efficient transmission of hydraulic energy and preventing pressure losses and system inefficiencies.

Hydraulic Fluid

The hydraulic fluid serves as the energy transfer medium and also provides lubrication, corrosion protection, and heat transfer. Different fluids are formulated for specific operating conditions, with viscosity being a key property affecting transmission efficiency.

Reservoir and Filters

The reservoir stores hydraulic fluid, allows for heat dissipation, and facilitates air separation. Filters remove contaminants from the fluid, protecting system components from wear and ensuring reliable operation of the hydraulic transmission.

Cooling Systems

Heat exchangers or coolers remove excess heat generated during hydraulic transmission operations. Maintaining proper fluid temperature is essential for system efficiency, fluid longevity, and preventing component damage.

System Operation

In operation, the hydraulic transmission system follows a cyclic process: The pump draws fluid from the reservoir and pressurizes it, creating flow. This pressurized fluid is directed through control valves to the appropriate actuators. As fluid enters an actuator, it creates mechanical motion (either linear or rotational) to perform work. After passing through the actuator, the fluid returns to the reservoir, completing the cycle.

The pressure in the system is determined by the load resistance at the actuator. According to Pascal's principle, the pressure remains consistent throughout the system, while the force exerted by actuators depends on the pressure and the effective area of the actuator piston or motor displacement.

This closed-loop energy transmission system allows for precise control of speed, force, and direction, making hydraulic systems highly versatile for a wide range of industrial applications.

3. Graphical Symbols in Hydraulic Transmission Systems

Graphical symbols are essential for representing hydraulic hydrostatic transmission diagram systems in engineering diagrams. These standardized symbols allow engineers, technicians, and operators to understand system design, operation, and maintenance requirements without language barriers. International standards, such as ISO 1219, define the symbols used in hydraulic circuit diagrams.

The symbols focus on the function of components rather than their physical appearance, allowing for clear representation of complex systems. This functional approach simplifies the design process and enhances communication in the field of hydraulic transmission.

Categories of Hydraulic Symbols

Fluid Power Lines and Connections

Working Line

Main pressure/return lines

Pilot Line

Control signal lines

Connection Point

Line termination

Pumps and Motors

Fixed Displacement Pump

Constant flow output

Variable Displacement Pump

Adjustable flow output

Hydraulic Motor

Rotary output device

Actuators

Single-Acting Cylinder

Force in one direction

Double-Acting Cylinder

Force in both directions

Control Valves

Check Valve

Allows one-way flow

Pressure Relief Valve

Protects system from overpressure

4/3 Directional Valve

Controls flow direction

Accessories

Reservoir

Fluid storage tank

Filter

Removes contaminants

Flow Control Valve

Regulates flow rate

Understanding these symbols is crucial for designing, analyzing, and troubleshooting hydraulic transmission systems. When combined in circuit diagrams, they provide a complete representation of how the system functions, showing the path of hydraulic fluid and how components interact to transmit power.

Modern computer-aided design (CAD) software includes libraries of these standard symbols, streamlining the design process for hydraulic transmission systems and ensuring consistency across different designs and manufacturers.

4. Advantages, Disadvantages and Applications of Hydraulic Transmission

Advantages

-

High Power Density

Hydraulic transmission systems provide exceptional power output relative to their size and weight, making them ideal for applications where space is limited but high force is required.

-

Precise Control

These systems offer precise control over speed, force, and direction, enabling accurate positioning and smooth operation in applications requiring fine movements.

-

High Force Capability

Hydraulic transmission can generate extremely high forces and torques, making them suitable for heavy-duty applications like metal forming and construction equipment.

-

Flexible Power Transmission

Hydraulic lines allow for flexible routing of power, enabling remote operation and positioning of actuators where mechanical transmission would be impractical.

-

Overload Protection

Pressure relief valves in hydraulic systems provide inherent overload protection, preventing damage to components during unexpected load increases.

-

Smooth Operation

Hydraulic transmission systems operate with minimal vibration and shock, providing smooth acceleration and deceleration compared to mechanical systems.

-

Compact Design

The high power density allows for more compact system designs, saving space in machinery and equipment.

Disadvantages

-

Fluid Leakage

Hydraulic transmission systems are prone to fluid leakage, which can cause environmental contamination, reduced efficiency, and safety hazards.

-

Maintenance Requirements

These systems require regular maintenance, including fluid changes, filter replacements, and seal inspections, to prevent failures and ensure proper operation.

-

Energy Losses

Hydraulic transmission systems can experience significant energy losses due to fluid friction and pressure drops, reducing overall efficiency compared to mechanical systems.

-

Temperature Sensitivity

Hydraulic fluid properties are temperature-dependent, affecting system performance in extreme temperature environments without proper thermal management.

-

Contamination Sensitivity

Hydraulic components are highly sensitive to contamination, requiring strict filtration and clean fluid handling to prevent wear and system failures.

-

Initial Cost

The initial cost of hydraulic transmission systems is often higher than mechanical systems due to the complexity of components and fluid handling requirements.

-

Noise

Hydraulic pumps and valves can generate significant noise, requiring additional sound insulation in noise-sensitive environments.

Applications

Hydraulic and transmission fluid systems find applications across numerous industries due to their unique combination of power, control, and flexibility. Below are some of the major application areas:

Construction Machinery

Hydraulic transmission is widely used in excavators, bulldozers, cranes, and loaders for their ability to generate high forces and provide precise control of multiple functions simultaneously.

Agricultural Equipment

Tractors, harvesters, and irrigation systems utilize hydraulic transmission for implements, steering, and lifting operations, providing power and control in demanding agricultural environments.

Industrial Machinery

Hydraulic presses, injection molding machines, and material handling equipment rely on hydraulic transmission for precise force application and control in manufacturing processes.

Automotive Industry

While mechanical and automatic transmissions dominate, hydraulic transmission is used in braking systems, power steering, and convertible tops for many vehicles.

Aerospace

Aircraft use hydraulic transmission for flight control surfaces, landing gear, and cargo handling due to their high power-to-weight ratio and reliability.

Marine Applications

Ships and offshore platforms utilize hydraulic transmission for steering, winches, cranes, and hatch operations, providing reliable performance in harsh marine environments.

Mobile Hydraulics

Mobile hydraulic transmission systems power various vehicles and equipment that move from one location to another. These systems are designed to be compact, efficient, and capable of operating in varying environmental conditions. Examples include emergency vehicles with hydraulic rescue tools, utility vehicles with lift platforms, and recreational vehicles with hydraulic leveling systems.

Stationary Hydraulics

Stationary hydraulic transmission systems are permanently installed in fixed locations such as factories and power plants. These systems often provide power for production lines, material handling systems, and heavy industrial processes. They typically benefit from more robust cooling systems and can be optimized for specific, consistent operating conditions.Optical Transceiver.

The future of hydraulic transmission continues to evolve with advancements in efficiency, digital control, and environmental performance. New fluid technologies, including biodegradable hydraulic oils, are addressing environmental concerns, while smart sensors and IoT integration are enabling predictive maintenance and optimized system performance.Electronic shelf labels.

As industries demand more efficient and sustainable power transmission solutions, hydraulic systems are adapting to meet these challenges while maintaining their core advantages of high power density and precise control. Related Lithium Battery Manufacturing.