Quality Hydrostatic Quality Control in Marine Engineering

Ensuring precision and reliability in hydrostatic systems through advanced testing and quality assurance protocols.

The Importance of Quality Hydrostatics in Marine Engineering

Quality hydrostatics is a critical aspect of marine engineering, ensuring the safety, efficiency, and reliability of vessels and offshore structures. Hydrostatic testing plays a vital role in verifying the structural integrity and performance of various components, from pipelines and pressure vessels to entire ship hulls.

At its core, quality hydrostatics involves the study of fluids at rest and the forces exerted by fluids on submerged surfaces. This field is essential for designing and maintaining marine structures that can withstand the immense pressures of underwater environments. By adhering to rigorous quality hydrostatic testing standards, engineers can ensure that marine vessels and structures meet the highest safety and performance criteria.

The implementation of quality hydrostatic testing protocols is crucial for identifying potential weaknesses in marine systems before they become critical issues. These tests involve subjecting components to controlled pressure conditions to evaluate their strength,密封性, and overall performance. By simulating real-world operating conditions, quality hydrostatics testing helps prevent catastrophic failures that could result in environmental damage, loss of life, and significant economic losses.

Quality hydrostatics testing is not limited to new construction; it is also a vital part of ongoing maintenance and inspection programs for existing marine structures. Regular hydrostatic testing helps identify wear and tear, corrosion, and other forms of degradation that may compromise the integrity of marine systems over time.

In today's competitive marine industry, adherence to quality hydrostatic standards is not only a matter of safety but also a business imperative. Vessels and offshore structures that meet or exceed these standards are more reliable, have longer service lives, and are more attractive to potential buyers and operators.

By investing in quality hydrostatics testing and maintenance, marine operators can reduce the risk of costly downtime, repairs, and replacements. This proactive approach to quality assurance ultimately leads to improved operational efficiency, enhanced safety, and greater profitability in the long run.

Key Principles of Quality Hydrostatics

Pascal's Principle

Pascal's principle is a fundamental concept in quality hydrostatics, stating that pressure applied to an enclosed fluid is transmitted undiminished to every part of the fluid and to the walls of its container. Mathematically, this principle is expressed as:

Where P is the pressure, F is the force applied, and A is the area over which the force is applied. This principle forms the basis for many hydraulic systems used in marine engineering, including steering mechanisms, lifting equipment, and hatch covers.

Archimedes' Principle

Archimedes' principle is another cornerstone of quality hydrostatics, explaining the buoyant force exerted on objects submerged in fluids. The principle states that an object immersed in a fluid experiences an upward buoyant force equal to the weight of the fluid displaced by the object. The formula for buoyant force is:

Where ρ is the fluid density, V is the volume of fluid displaced, and g is the acceleration due to gravity. This principle is essential for determining the stability and flotation characteristics of marine vessels.

Hydrostatic Pressure Distribution

In quality hydrostatics, understanding pressure distribution in fluids at rest is crucial for designing safe and efficient marine structures. The pressure at any point in a fluid at rest varies with depth according to the hydrostatic pressure formula:

Where h is the depth below the surface. This relationship means that pressure increases linearly with depth, a factor that must be carefully considered in the design of submarines, offshore platforms, and other submersible structures.

Hydrostatic Forces on Surfaces

The calculation of hydrostatic forces on submerged surfaces is a critical aspect of quality hydrostatics in marine engineering. These forces are essential considerations in the design of ship hulls, dams, and other marine structures. The hydrostatic force on a surface can be calculated using:

Where Pavg is the average pressure on the surface, and A is the area of the surface. The point at which this force acts, known as the center of pressure, is also a key parameter in structural design.

International Standards for Quality Hydrostatics

Adherence to international standards is paramount in ensuring quality hydrostatics in marine engineering. These standards provide comprehensive guidelines for testing procedures, equipment calibration, and performance criteria, ensuring consistency and reliability across the industry.

ISO 10802:2020

ISO 10802:2020 specifies site hydrostatic acceptance tests for installed pressure and non-pressure ductile iron pipelines used for conveying water and other liquids. This standard outlines the procedures for conducting hydrostatic tests to verify the integrity and performance of pipeline systems.

Key requirements include test pressure calculations, duration specifications, and acceptance criteria for leakage and structural deformation.

ASME BPVC Section VIII

The ASME Boiler and Pressure Vessel Code (BPVC) Section VIII provides rules for the design, fabrication, inspection, and testing of pressure vessels. This standard includes detailed provisions for hydrostatic testing to ensure the structural integrity of pressure-containing components.

Hydrostatic test pressures are typically specified as 1.3 times the design pressure, with specific holding times and leakage allowances.

API 570

API 570 is the American Petroleum Institute's standard for the inspection, repair, alteration, and rerating of in-service piping systems. This standard includes requirements for hydrostatic testing of piping systems in the petroleum and chemical industries.

API 570 requires pipelines to be tested at 1.5 times their maximum operating pressure, with test pressure maintained for a minimum of 4 hours.

ISO 21173:2019

ISO 21173:2019 specifies a test method for the hydrostatic pressure test for pressure hull and buoyancy materials of submersibles. This standard covers both manned and unmanned submersible vehicles.

The standard includes procedures for tightness testing, hydrostatic pressure testing, continuous pressurization and depressurization tests, and long-term static load tests.

Hydrostatic Testing Parameters by Standard

| Standard | Application | Test Pressure | Minimum Hold Time |

|---|---|---|---|

| ISO 10802:2020 | Ductile iron pipelines | 1.5 × Design pressure | 30 minutes |

| ASME BPVC Section VIII | Pressure vessels | 1.3 × Design pressure | 30 minutes |

| API 570 | Pipelines | 1.5 × Maximum operating pressure | 4 hours |

| ISO 21173:2019 | Submersibles | Variable (depth-dependent) | Variable (application-dependent) |

| NB/T 10790-2021 | Water treatment equipment | 1.5 × Design pressure (general) 1.25 × Design pressure (special materials) |

30 minutes (minimum) |

Authority Citation

According to the American Society of Mechanical Engineers (ASME), "Hydrostatic testing is a fundamental method for verifying the structural integrity and leak tightness of pressure-containing components. When properly performed in accordance with recognized standards, these tests provide valuable assurance that equipment will operate safely under design conditions."

Source: ASME BPVC Section VIII, Division 1, Mandatory Appendix A - Hydrostatic Test. Available at: https://www.asme.org/products/codes-standards/bpvc-section-viii-division-1

Quality Hydrostatic Testing Methods

Quality hydrostatic testing involves a variety of methods tailored to specific applications and industry requirements. These methods are designed to evaluate the performance and integrity of marine systems under controlled pressure conditions.

Standard Hydrostatic Pressure Test

The standard hydrostatic pressure test is the most common method used to verify the integrity of pressure vessels, pipelines, and other marine components. This method involves:

- Filling the component with a test fluid, typically water

- Evacuating air from the system

- Gradually increasing pressure to the specified test level

- Maintaining the test pressure for a specified duration

- Monitoring for pressure loss and visual inspection for leaks

- Gradually releasing pressure and draining the system

This method is widely used in quality hydrostatics programs due to its simplicity, reliability, and ability to detect both visible and microscopic defects.

Hydrostatic Leak Testing

Hydrostatic leak testing is a specialized method focused on detecting and quantifying leaks in marine systems. This method is particularly important for components that handle hazardous materials or operate in sensitive environments. Key techniques include:

- Bubble testing with soap solution

- Dye penetrant testing

- Ultrasonic leak detection

- Pressure decay testing

- Mass spectrometer leak detection

According to ASTM E1003-13, hydrostatic leak testing is effective for detecting leakage rates of 4.5 × 10-9 mol/s (1 × 10-4 std cm3/s) or larger.

Advanced Hydrostatic Testing Techniques

Cyclic Pressure Testing

Involves subjecting components to repeated pressure cycles to simulate real-world operating conditions and evaluate fatigue resistance.

Hydrostatic Fatigue Testing

Tests the ability of materials and components to withstand repeated pressure fluctuations over an extended period.

Instrumented Hydrostatic Testing

Uses advanced sensors and data acquisition systems to monitor pressure, strain, and displacement during testing for detailed analysis.

Quality Hydrostatics Testing Equipment

Acceptance Criteria for Quality Hydrostatics Testing

Clear acceptance criteria are essential for evaluating the results of hydrostatic tests. These criteria typically include:

| Criteria | Description | Typical Standard |

|---|---|---|

| Pressure Loss | Maximum allowable pressure drop during the test period | ≤ 1% of test pressure |

| Visible Leaks | No visible signs of leakage, including droplets or wetting | Zero tolerance |

| Structural Deformation | No permanent deformation or distortion of the component | Return to original dimensions after pressure release |

| Weld Integrity | No cracks, porosity, or other defects in welded areas | Compliance with NB/T 47013 |

Applications of Quality Hydrostatics in Marine Engineering

Quality hydrostatics plays a vital role in various aspects of marine engineering, ensuring the safety, efficiency, and reliability of marine systems and structures. From ship design to offshore operations, hydrostatic principles and testing methods are applied across the industry.

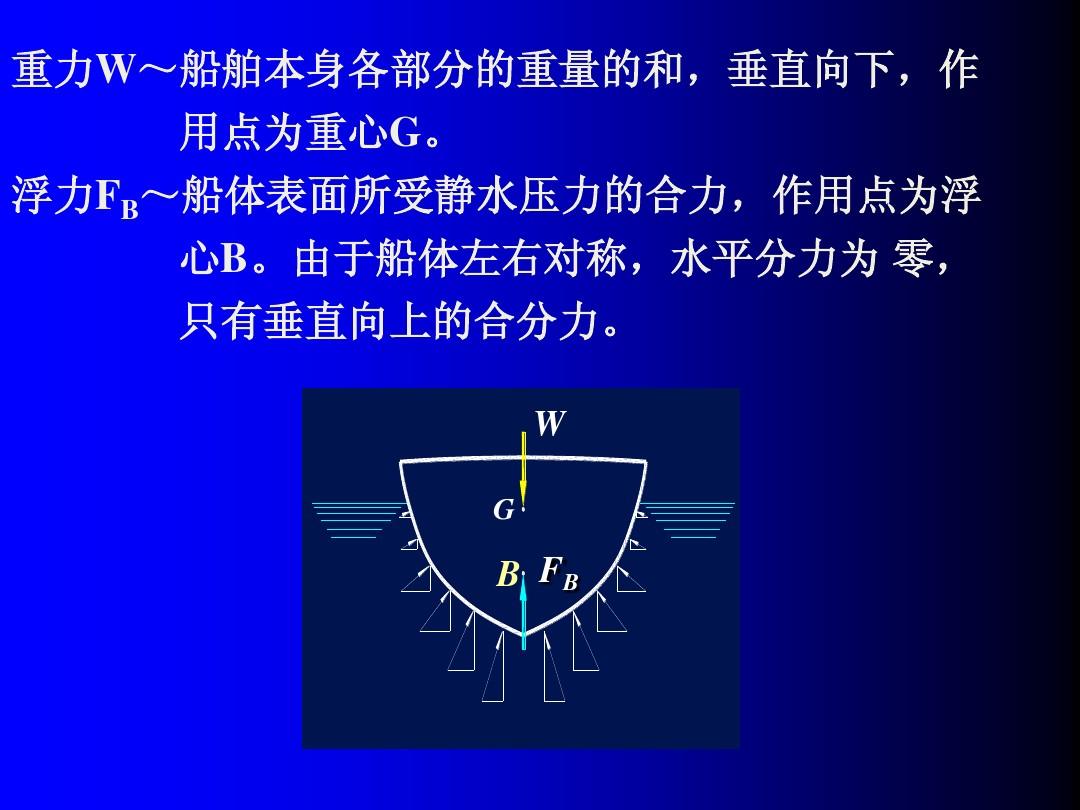

Ship Design and Stability

In ship design, quality hydrostatics is essential for determining buoyancy, stability, and performance characteristics. Naval architects use hydrostatic calculations to:

- Calculate ship displacement and center of buoyancy

- Determine metacentric height (GM) for stability assessment

- Develop righting lever (GZ) curves to evaluate capsizing resistance

- Optimize hull form for minimal resistance and maximum efficiency

- Assess damage stability and flooding scenarios

Modern hydrostatic analysis tools, such as NAPA's hydrostatics and stability solutions, enable ship designers to perform accurate calculations and ensure compliance with international regulations.

Offshore Structures

Quality hydrostatics is critical for the design and operation of offshore structures, including oil platforms, wind turbines, and subsea systems. Key applications include:

- Analysis of platform stability under various loading conditions

- Calculation of hydrostatic forces on subsea equipment

- Design of risers and pipelines for deepwater applications

- Assessment of floating structure motions and responses

- Hydrostatic testing of subsea components for leak integrity

For submersibles, ISO 21173:2019 specifies hydrostatic pressure test methods for pressure hulls and buoyancy materials, ensuring these critical components can withstand the extreme pressures of deep-sea environments.

Marine Pipeline Systems

quality hydrostatic testing is a mandatory requirement for marine pipeline systems, ensuring their integrity and safety. Key aspects include:

Installation Testing

Hydrostatic testing of newly installed pipelines to verify weld integrity and system tightness before commissioning.

Maintenance Testing

Periodic hydrostatic testing of existing pipelines to detect corrosion, erosion, and other forms of degradation.

Repair Verification

Hydrostatic testing after pipeline repairs or modifications to ensure the integrity of the repaired section.

ISO 10802:2020 provides specific guidelines for hydrostatic testing of ductile iron pipelines, while API 570 covers testing requirements for petroleum and chemical industry pipelines.

Hydrostatic Testing in Shipyards

Shipyards rely heavily on quality hydrostatic testing throughout the construction and maintenance process. Key applications include:

| Component | Test Purpose | Test Standard |

|---|---|---|

| Hull Structure | Verify watertight integrity of compartments | SOLAS, Classification Society Rules |

| Ballast Tanks | Ensure structural integrity and watertightness | IMO PSPC, IACS UR S20 |

| Fuel Tanks | Check for leaks and structural integrity | SOLAS Chapter II-2 |

| Hydraulic Systems | Test pressure rating and leak tightness | ISO 1402, SAE J1273 |

| Steam Boilers | Verify pressure containment capability | ASME BPVC Section I |

Frequently Asked Questions About Quality Hydrostatics

What is the purpose of hydrostatic testing?

Hydrostatic testing is performed to verify the structural integrity and leak tightness of pressure-containing components and systems. It involves filling the component with a liquid, typically water, and pressurizing it to a specified level to simulate operating conditions and detect any potential weaknesses or leaks.

How often should hydrostatic testing be performed?

The frequency of hydrostatic testing depends on several factors, including the type of equipment, operating conditions, and applicable regulations. For example, API 570 requires periodic hydrostatic testing of pipelines based on their corrosion rate and service conditions. Generally, critical components may require testing every 3-5 years, while less critical systems may be tested every 10 years or as specified by the manufacturer.

What is the difference between hydrostatic and pneumatic testing?

Hydrostatic testing uses a liquid (usually water) as the test medium, while pneumatic testing uses a gas (typically air or nitrogen). Hydrostatic testing is generally safer because liquids are incompressible, reducing the risk of explosive energy release if a failure occurs. Pneumatic testing is used when the system cannot be filled with liquid or when a gas medium is required for specific test conditions.

What are the safety considerations for hydrostatic testing?

Safety is paramount during hydrostatic testing. Key considerations include: ensuring the test area is clear of personnel during testing, using appropriate pressure relief devices, gradually increasing and decreasing pressure, and having emergency procedures in place. Personnel should be properly trained in hydrostatic testing procedures and safety protocols.

What causes pressure loss during hydrostatic testing?

Pressure loss during hydrostatic testing can be caused by several factors, including: leaks in the system, temperature changes affecting the test fluid, and air pockets in the system. It is important to differentiate between acceptable pressure loss due to temperature variations and pressure loss due to actual leaks.

How is the test pressure determined?

Test pressure is typically specified as a multiple of the design pressure or maximum operating pressure. For example, ASME BPVC Section VIII specifies a test pressure of 1.3 times the design pressure for pressure vessels, while API 570 requires pipelines to be tested at 1.5 times their maximum operating pressure. The specific test pressure may also be influenced by material properties, temperature, and regulatory requirements.

What is the significance of the hold time in hydrostatic testing?

The hold time is the duration during which the test pressure is maintained. This allows for pressure stabilization and provides time to detect leaks that may not be immediately apparent. The required hold time varies depending on the component size, test pressure, and applicable standard, ranging from 30 minutes for small components to several hours for large systems.

How are hydrostatic test results documented?

Proper documentation of hydrostatic test results is essential for quality assurance and regulatory compliance. Test records should include: equipment identification, test date, test fluid, test pressure and duration, pressure readings over time, any observed leaks or anomalies, and the signature of the testing personnel. These records should be retained for the life of the equipment or as required by regulatory authorities.

Glossary of Quality Hydrostatics Terms

Key Terms

- Buoyancy

- The upward force exerted by a fluid on a submerged object, equal to the weight of the fluid displaced by the object.

- Center of Buoyancy (B)

- The point through which the buoyant force acts, corresponding to the centroid of the displaced volume of fluid.

- Center of Gravity (G)

- The point through which the weight of an object acts.

- Design Pressure

- The maximum pressure for which a component is designed to operate under specified conditions.

- Displacement

- The weight of the fluid displaced by a floating or submerged object, equal to the weight of the object itself.

- Hydrostatic Pressure

- The pressure exerted by a fluid at rest, varying with depth according to the formula P = ρgh.

- Metacentric Height (GM)

- The distance between the center of gravity (G) and the metacenter (M), a measure of a ship's initial stability.

- Metacenter (M)

- The intersection point of the vertical line through the center of buoyancy and the original vertical line through the center of gravity when a ship is inclined.

Additional Terms

- Righting Lever (GZ)

- The horizontal distance between the center of gravity (G) and the center of buoyancy (B) when a ship is inclined, multiplied by the sine of the angle of inclination.

- Righting Moment

- The moment generated by the weight of the ship and the buoyant force when the ship is inclined, calculated as the product of the righting lever and the displacement.

- Specific Gravity

- The ratio of the density of a substance to the density of a reference substance (usually water at 4°C).

- Test Pressure

- The pressure to which a component is subjected during hydrostatic testing, typically a multiple of the design pressure.

- Trim

- The longitudinal inclination of a ship, measured as the difference in draft between the bow and stern.

- Waterplane Area

- The area of the ship's hull at the waterline, an important parameter for calculating stability and buoyancy.

- Waterplane Inertia

- A measure of the ship's resistance to rolling, calculated as the moment of inertia of the waterplane area about the longitudinal axis.

- Zoning

- The process of dividing a ship's hull into watertight compartments to limit flooding in case of damage.

Enhance Your Marine Engineering Projects with Quality Hydrostatics

Ensure the safety, reliability, and performance of your marine systems through rigorous hydrostatic testing and analysis.

Learn more