Hydraulic Pumps and Hydraulic Motors

Comprehensive guide to hydraulic systems components, operation principles, and applications

Hydraulic systems play a crucial role in modern industry, providing powerful, precise, and reliable means of transmitting power—all made possible by hydraulic transmission (the fundamental technology behind hydraulic power transfer, relying on fluid pressure to move energy). At the heart of these systems are hydraulic pumps and the Hydraulic motor, which are the key components of hydraulic transmission: they work together to convert energy between mechanical and fluid forms, directly enabling the power transmission capabilities of hydraulic systems.

A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. It generates flow with sufficient power to overcome pressure induced by the load at the pump outlet. The fundamental purpose of a hydraulic pump is to move fluid from one location to another within a hydraulic system.

In contrast, a Hydraulic motor performs the opposite function, converting hydraulic energy back into mechanical energy. This mechanical energy is typically in the form of rotational motion, which can then be used to drive various types of machinery and equipment.

Both hydraulic pumps and the Hydraulic motor operate based on the principles of fluid dynamics and Pascal's law, which states that pressure applied to an enclosed fluid is transmitted undiminished to all portions of the fluid and the walls of its container.

The efficiency of a hydraulic system largely depends on the performance characteristics of its pump and Hydraulic motor. Factors such as pressure rating, flow rate, speed, and volumetric efficiency all contribute to the overall system performance.

Hydraulic systems offer several advantages over mechanical and electrical systems, including high power density, precise speed and position control, overload protection, and the ability to transmit power over long distances with minimal loss. These advantages make hydraulic systems indispensable in various industries, including construction, manufacturing, agriculture, aerospace, and marine applications.

Key Components of Hydraulic Systems

- Hydraulic pumps - generate fluid flow and pressure

- Hydraulic motor - converts fluid energy to mechanical energy

- Valves - control direction, pressure, and flow rate

- Reservoir - stores hydraulic fluid

- Filters - maintain fluid cleanliness

- Piping and hoses - connect system components

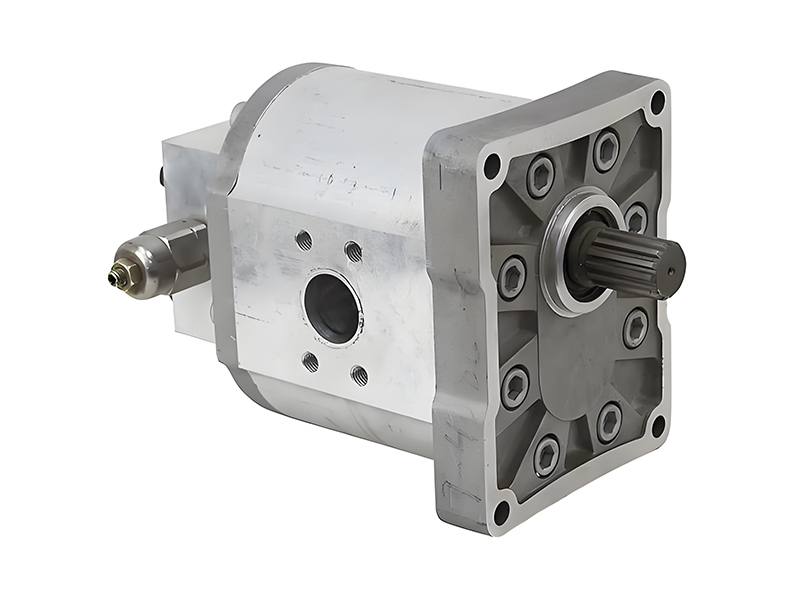

Gear pumps—often equipped with a hydraulic pump gearbox (a gear-driven accessory that syncs with the pump’s internal gears to optimize power input)—are one of the most common types of hydraulic pumps, valued for their simplicity, reliability, and cost-effectiveness. Both the gear pump and its matching hydraulic pump gearbox rely on precision gear meshing: the pump uses meshing gears to displace fluid within a hydraulic system, while the gearbox uses meshing gears to fine-tune the mechanical power fed into the pump, ensuring efficient operation across different load conditions.

The basic design of a gear pump consists of two intermeshing gears housed within a close-fitting casing. One gear is driven (the driver gear), while the other gear (the driven gear) rotates as a result of its meshing with the driver gear. As the gears rotate, fluid is trapped between the teeth of the gears and the casing, and is carried around the circumference of the gears.

When the teeth of the two gears mesh again on the discharge side of the pump, the fluid is forced out of the pump outlet under pressure. This meshing action creates a seal that prevents fluid from flowing back to the inlet side of the pump.

There are two main types of gear pumps: external gear pumps and internal gear pumps. External gear pumps feature two identical external gears that mesh together, while internal gear pumps have one larger external gear that meshes with a smaller internal gear.

Gear pumps are known for their compact design, high volumetric efficiency, and ability to handle a wide range of viscosities. They are typically used in applications requiring moderate pressure (up to 250 bar) and flow rates. While not as efficient as some other pump types at high pressures, their simplicity makes them easy to maintain and repair.

When paired with a Hydraulic motor, gear pumps provide an economical solution for many mobile and industrial hydraulic systems. The combination of a gear pump and Hydraulic motor is commonly found in applications such as machine tools, material handling equipment, and agricultural machinery.

Gear Pump Characteristics

Advantages and Disadvantages of Gear Pumps

Advantages

- Simple design with few moving parts

- Highly reliable and durable

- Compact size and lightweight

- Cost-effective compared to other pump types

- Can handle a wide range of fluid viscosities

- Easy to maintain and repair

Disadvantages

- Limited pressure capability compared to piston pumps

- Generally noisier than vane or piston pumps

- Not suitable for variable displacement applications

- Can cause fluid contamination due to metal-to-metal contact

- Lower overall efficiency at high pressures

Vane pumps are positive displacement pumps that use a set of vanes mounted radially in a rotating rotor to move fluid through the pump. They offer a good balance between efficiency, pressure capability, and cost—traits that make them a preferred fluid supply component in hydrostatic drive systems (hydraulic power transmission setups that rely on high-pressure fluid to transfer torque, common in heavy machinery like forklifts or agricultural tractors). This compatibility with hydrostatic drive further expands the vane pumps’ utility, as their stable fluid output ensures the drive system maintains consistent speed and torque control, reinforcing why vane pumps are popular in many industrial applications.

The basic construction of a vane pump includes a circular rotor with slots that hold rectangular vanes. The rotor is mounted eccentrically within a cam ring (stator). As the rotor rotates, centrifugal force pushes the vanes outward, causing them to maintain contact with the inner surface of the cam ring. This creates sealed chambers between adjacent vanes, the rotor, and the cam ring.

As the rotor turns, the volume of these chambers increases on the inlet side of the pump, drawing fluid in. On the discharge side, the volume of the chambers decreases as the vanes are pushed back into their slots by the cam ring, forcing fluid out of the pump under pressure. This design allows for smooth fluid flow with relatively low pulsation.

There are several types of vane pumps, including fixed displacement and variable displacement designs. Variable displacement vane pumps can adjust their output flow by moving the cam ring relative to the rotor, changing the eccentricity. This allows for flow control without the need for additional valves.

Vane pumps are known for their quiet operation, high volumetric efficiency, and ability to handle thin fluids. They typically operate at pressures up to 175 bar, though some high-performance models can reach 210 bar. Their design minimizes metal-to-metal contact, reducing wear and extending service life.

When paired with a Hydraulic motor, vane pumps provide efficient power transmission in applications such as machine tools, plastic injection molding machines, and automotive systems. The smooth flow characteristics of vane pumps make them particularly suitable for applications where precise control of the Hydraulic motor speed is required.

Vane Pump Operation Principles

-

1

Rotor Rotation

The rotor turns, causing vanes to extend by centrifugal force

-

2

Fluid Intake

Increasing chamber volume draws fluid into the pump

-

3

Fluid Transport

Fluid is carried around the pump in sealed chambers

-

4

Fluid Discharge

Decreasing chamber volume forces fluid out under pressure

-

5

Vane Retraction

Vanesslide back into rotor slots as cam ring diameter decreases

Types of Vane Pumps

Unbalanced Vane Pumps

Simple design with rotor eccentric to cam ring. Pressure loading is unbalanced, limiting pressure capability. Used in low to medium pressure applications.

Balanced Vane Pumps

Feature dual inlet and outlet ports with symmetric cam ring. Balances hydraulic forces, allowing higher pressure operation with reduced bearing loads.

Variable Displacement Vane Pumps

Allow flow rate adjustment by changing rotor eccentricity. Provide energy savings by matching flow to demand, commonly used with a Hydraulic motor in variable speed applications.

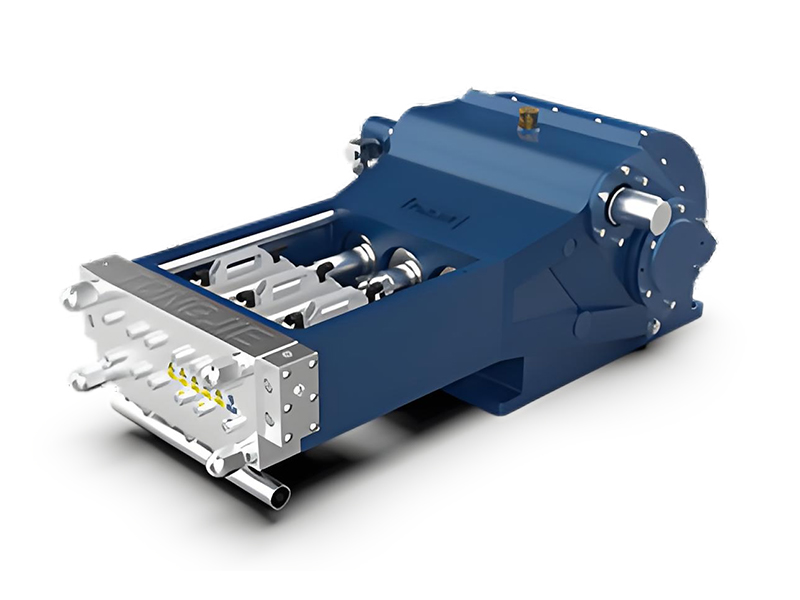

Demanding hydraulic applications like hydrostatic transmission (a key power transmission solution for machinery requiring precise speed control and heavy load handling, which relies on high-pressure fluid to drive motion) depend heavily on pumps that can deliver consistent high pressure and efficiency—and piston pumps excel in this role. Piston pumps are positive displacement pumps that use reciprocating pistons to move fluid through the pump. They are known for their high efficiency, pressure capability, and versatility: their robust pressure output meets the hydrostatic transmission’s need for reliable power transfer, while their versatility allows integration into different transmission configurations, making them suitable for such demanding hydraulic applications.

The fundamental design of a piston pump includes a cylinder block containing multiple pistons arranged in a circular pattern. As the cylinder block rotates, the pistons reciprocate (move back and forth) within their bores. This reciprocating motion creates a pumping action as fluid is drawn into the cylinder on the intake stroke and forced out on the discharge stroke.

There are two main categories of piston pumps: axial piston pumps and radial piston pumps. In axial piston pumps, the pistons are arranged parallel to the pump's drive shaft. The reciprocating motion is typically achieved by a swash plate or a bent axis design. In radial piston pumps, the pistons are arranged radially around the drive shaft, with fluid displacement occurring as the pistons move outward and inward relative to the shaft centerline.

One of the key advantages of piston pumps is their ability to provide variable displacement. By adjusting the angle of the swash plate in axial piston pumps or the eccentricity in radial piston pumps, the output flow can be varied while maintaining constant speed. This allows for precise control of system pressure and flow, making them ideal for applications where energy efficiency is important.

Piston pumps can operate at much higher pressures than gear or vane pumps, typically ranging from 210 to 350 bar, with some specialized models capable of reaching 700 bar or more. They also offer superior volumetric efficiency, often exceeding 95% in high-quality designs.

When paired with a high-performance Hydraulic motor, piston pumps form the heart of many heavy-duty hydraulic systems. This combination is commonly found in construction equipment, mining machinery, and industrial presses where high power density and precise control are required. The ability of piston pumps to maintain efficiency at high pressures makes them particularly well-suited for driving a Hydraulic motor in applications requiring significant force or torque.

Piston Pump Performance Characteristics

Axial vs. Radial Piston Pumps

| Characteristic | Axial Piston Pumps | Radial Piston Pumps |

|---|---|---|

| Piston Arrangement | Parallel to drive shaft | Radial around drive shaft |

| Pressure Range | 210-350 bar (up to 700 bar) | 250-420 bar (up to 1000 bar) |

| Speed Capability | High (up to 3000 RPM) | Moderate (up to 1800 RPM) |

| Volumetric Efficiency | 90-98% | 92-99% |

| Size/Weight | Compact for power output | Larger for equivalent power |

| Cost | High | Very High |

| Common Applications | Mobile hydraulics, industrial machinery | Heavy industrial, high-pressure systems |

| Compatibility with Hydraulic motor | Excellent for most applications | Ideal for high-torque Hydraulic motor applications |

Selecting the appropriate hydraulic pump for a specific application requires careful consideration of various performance characteristics and operational requirements, including for contexts like what is hydrostatic transmission. The following comparison highlights the key differences between gear, vane, and piston pumps, along with their typical applications when paired with a Hydraulic motor.

Performance Parameter Comparison

Gear Pumps

Typical Applications

- Machine tool lubrication systems

- Automotive power steering

- Agricultural equipment

- Small material handling systems

- Low-pressure industrial machinery

Key Advantages in Applications

Cost-effectiveness and simplicity make gear pumps ideal for applications where moderate pressure and flow are sufficient, and where system complexity and initial cost are primary concerns.

Vane Pumps

Typical Applications

- Plastic injection molding machines

- Hydraulic presses

- Automatic transmission systems

- Machine tools requiring precise control

- Automation and robotics systems

Key Advantages in Applications

Smooth operation and good efficiency make vane pumps suitable for applications requiring steady flow, moderate pressure, and where noise levels must be kept to a minimum.

Piston Pumps

Typical Applications

- Heavy construction equipment

- High-pressure industrial presses

- Mining machinery

- Marine hydraulic systems

- Aerospace applications

Key Advantages in Applications

High pressure capability and efficiency make piston pumps ideal for heavy-duty applications requiring maximum power density and precise control of large Hydraulic motor systems.

Selection Criteria for Hydraulic Pumps

-

1

Operating Pressure Requirements

Consider both maximum and operating pressure needs, ensuring compatibility with the Hydraulic motor and system components.

-

2

Flow Rate Requirements

Calculate required flow based on system demand, including all branches and the Hydraulic motor needs.

-

3

Speed Range

Consider the pump's operating speed range and its compatibility with the drive system.

-

4

Efficiency Considerations

Evaluate overall efficiency at operating conditions to minimize energy consumption.

-

5

Fluid Compatibility

Ensure pump materials are compatible with the hydraulic fluid being used.

-

6

Environmental Factors

Consider temperature, contamination, and mounting orientation constraints.

-

7

Cost Considerations

Evaluate initial cost against long-term operating and maintenance expenses.

-

8

System Integration

Ensure compatibility with other system components, particularly the Hydraulic motor and control valves.

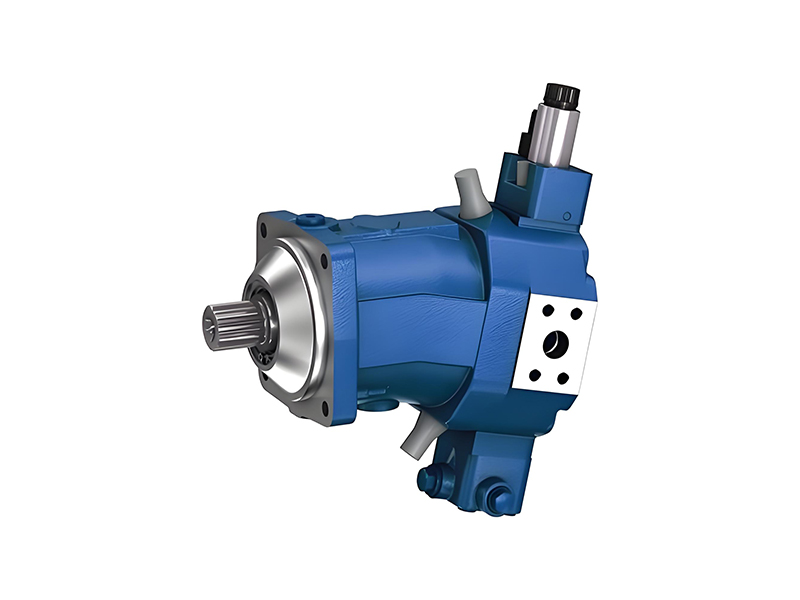

A Hydraulic motor is a mechanical actuator that converts hydraulic energy (pressurized fluid) into mechanical energy (rotary motion and torque); this includes the hydrostatic motor. It is essentially the reverse of a hydraulic pump, although many pump designs can function as motors when operated in reverse.

The operation of a Hydraulic motor relies on the same fundamental principles as hydraulic pumps, but in reverse. Pressurized fluid enters the motor and acts on internal components (gears, vanes, or pistons), creating rotational motion. The amount of torque produced by a Hydraulic motor is proportional to the system pressure and the motor's displacement, while the speed is primarily determined by the flow rate of the fluid entering the motor.

Like hydraulic pumps, Hydraulic motors are available in several different designs, each with its own characteristics and applications. The main types include gear motors, vane motors, and piston motors, which correspond to the pump types and share similar construction principles.

Gear motors are simple, rugged, and cost-effective, making them suitable for low to medium torque applications. They operate on the same principle as gear pumps, with fluid pressure causing the gears to rotate. Vane motors offer better efficiency and smoother operation than gear motors, with good speed control capabilities.

Piston motors are the most efficient type of Hydraulic motor and can produce the highest torque and operate at the highest pressures. They are available in both axial and radial piston designs, with axial piston motors being more common in mobile and industrial applications. Piston motors provide excellent control over speed and torque, making them ideal for applications requiring precise movement.

Hydraulic motors are used in a wide range of applications, from small machinery to large industrial equipment. Common uses include conveyor systems, winches, agricultural machinery, construction equipment, and robotics. The combination of a properly matched hydraulic pump and Hydraulic motor provides a powerful, efficient means of transmitting power in situations where mechanical or electrical systems would be impractical.

Hydraulic Motor Performance Parameters

Displacement

The volume of fluid required to rotate the motor output shaft one full revolution, typically measured in cm³/rev or in³/rev. Determines the relationship between flow rate and speed, and torque and pressure.

Speed Range

The operating speed range of the Hydraulic motor, from minimum to maximum rotational speed (RPM). Different motor types have characteristic speed ranges, with some designs optimized for high speed and low torque, others for low speed and high torque.

Torque Output

The rotational force produced by the Hydraulic motor, directly related to system pressure and motor displacement. Starting torque (breakaway torque) and running torque are important considerations for application suitability.

Efficiency

Hydraulic motor efficiency includes volumetric efficiency (leakage) and mechanical efficiency (friction losses). Overall efficiency affects heat generation and energy consumption in the system.

Types of Hydraulic Motors

Gear Motors

Simple design similar to gear pumps, with fluid pressure driving meshing gears. Known for their ruggedness and low cost.

Key Characteristics:

- • Pressure: Up to 200 bar

- • Speed: Up to 3000 RPM

- • Efficiency: 70-85%

- • Torque: Low to moderate

Vane Motors

Utilize sliding vanes in a rotor to convert fluid pressure to rotational motion. Offer better efficiency than gear motors.Optical Transceiver.

Key Characteristics:

- • Pressure: Up to 180 bar

- • Speed: Up to 2500 RPM

- • Efficiency: 75-90%

- • Torque: Moderate

Piston Motors

Highest performance Hydraulic motor type, using reciprocating pistons to generate rotational motion. Available in axial and radial designs.Electronic shelf labels.

Key Characteristics:

- • Pressure: Up to 420 bar

- • Speed: Up to 5000 RPM

- • Efficiency: 85-95%

- • Torque: High

Hydraulic Motor Applications

Mobile Equipment

- Construction machinery (excavators, loaders)

- Agricultural equipment (tractors, harvesters)

- Mining vehicles and equipment

- Material handling equipment

- Forestry machinery

Industrial Applications

- Conveyor systems and material handling

- Machine tools and manufacturing equipment

- Robotics and automated systems

- Winches, hoists, and lifting equipment

- View lithium battery technology materials