A hydraulic control valve is a crucial component in hydraulic systems—relating to what are hydraulics powered by—responsible for regulating the flow, pressure, and direction of hydraulic fluid to ensure optimal performance of machinery and equipment. These valves act as the "brain" of hydraulic systems, directing fluid where it's needed, when it's needed, and at the right pressure and flow rate.

The hydraulic control valve operates by opening, closing, or partially obstructing passageways in the hydraulic circuit. This precise control allows for the smooth operation of hydraulic cylinders and motors, enabling the performance of various tasks with different force and speed requirements. From heavy machinery in construction to precision equipment in manufacturing, the hydraulic control valve plays an indispensable role.

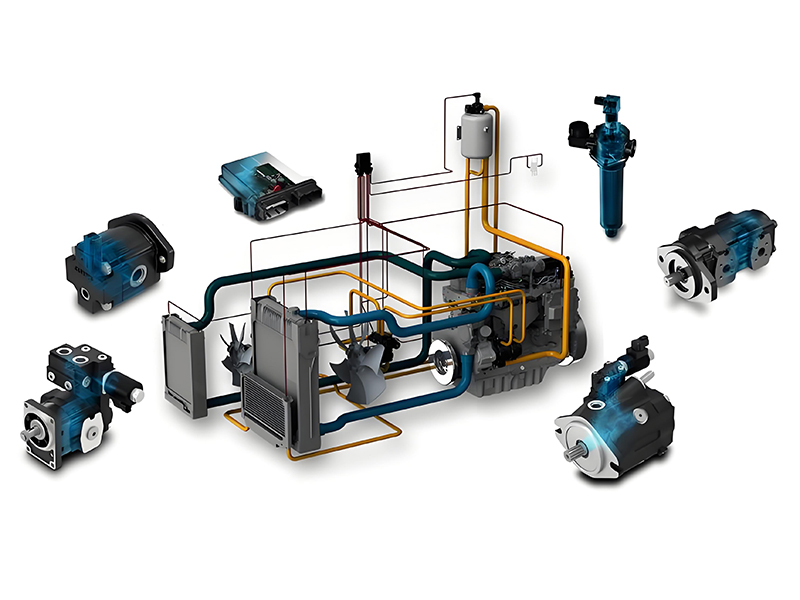

Modern hydraulic control valves are engineered to meet stringent performance standards, offering reliability, durability, and precise control even in harsh operating environments. They come in various configurations, sizes, and pressure ratings to accommodate the diverse needs of different industries, including agriculture, construction, mining, manufacturing, and aerospace.

Understanding the different types of hydraulic control valves, their functions, and applications is essential for anyone involved in the design, operation, maintenance, or troubleshooting of hydraulic systems. This comprehensive guide explores the various categories of hydraulic control valves, their working principles, and their practical applications.

Key Functions of a Hydraulic Control Valve

- Regulate fluid flow direction to control actuator movement

- Control fluid pressure to prevent system overload and ensure safe operation

- Adjust flow rate to control the speed of hydraulic actuators

- Direct fluid to different branches of the hydraulic system as needed

- Isolate components for maintenance or in emergency situations

- Provide proportional control for precise movement and force application

Directional control valves, key to hydro transmission, are fundamental components in any hydraulic system, primarily responsible for controlling the path of hydraulic fluid flow. As a critical type of hydraulic control valve, they determine which path the fluid takes and in which direction it flows, thereby controlling the movement of hydraulic actuators such as cylinders and motors.

The basic operation of a directional control valve involves a movable element (typically a spool, poppet, or rotary valve) that opens or closes passages within the valve body. By positioning this element, the operator or control system can direct fluid to different parts of the hydraulic circuit.

These valves are classified based on several criteria, including the number of ports, the number of positions, the method of actuation, and the type of spool configuration. The most common notation used to describe directional control valves is the number of ports followed by the number of positions (e.g., 4/3 valve indicates 4 ports and 3 positions).

Common Types of Directional Control Valves

Check Valves

The simplest type of directional control valve, allowing fluid to flow in one direction only while preventing reverse flow. They act as one-way doors in hydraulic systems, automatically opening when pressure is applied in the desired direction and closing when pressure tries to reverse.

2-Way Valves

These valves control flow between two ports, either allowing flow (open) or blocking it (closed). They are commonly used as shut-off valves in hydraulic systems to isolate components or sections of the circuit when needed.

4-Way Valves

The most common type in mobile and industrial hydraulics, featuring four ports (pressure, tank, and two cylinder ports). They control the direction of fluid to and from hydraulic cylinders, enabling extension and retraction.

Actuation Methods for Directional Control Valves

| Actuation Method | Description | Common Applications |

|---|---|---|

| Manual | Operated by hand lever, knob, or pedal | Small machinery, emergency controls |

| Hydraulic | Actuated by fluid pressure signals | Large industrial systems, remote operation |

| Pneumatic | Operated by compressed air | Factory automation, explosive environments |

| Electric | Solenoid-operated for precise control | Automated systems, CNC machinery |

| Mechanical | Cam, roller, or linkage activated | Limit controls, sequence operations |

Directional control valves play a vital role in determining the overall functionality of a hydraulic system. By effectively managing the flow path of hydraulic fluid, these valves enable the precise control of actuators, making them indispensable in countless industrial and mobile applications. The selection of the appropriate directional control valve depends on factors such as flow rate requirements, pressure rating, response time, actuation method, and environmental conditions.

Modern directional control valves often incorporate advanced features such as reduced pressure drops, improved contamination resistance, and enhanced durability to meet the demanding requirements of today's hydraulic systems. As with any hydraulic control valve, proper maintenance and selection are crucial to ensuring long service life and reliable operation.

Pressure control valves are essential components designed to regulate and maintain the pressure levels within a hydraulic system. As a critical category of hydraulic control valve, they prevent system overpressure, which could lead to component damage, inefficiency, or even catastrophic failure. These valves ensure that hydraulic pressure remains within safe and operational limits while providing the necessary force for system functions involving hydrostatic energy.

The operation of a pressure control valve typically involves a sensing element (such as a piston, diaphragm, or poppet) that responds to system pressure. When pressure reaches a predetermined level, the valve opens to relieve excess pressure, redirect fluid flow, or signal other components in the system.

Pressure control valves are vital for protecting hydraulic components from damage due to excessive pressure. They also enable pressure regulation for different parts of a hydraulic system that may require varying pressure levels to perform their specific functions.

Types of Pressure Control Valves

Pressure Relief Valves

The most common type of pressure control valve, designed to open when system pressure exceeds a preset limit, diverting excess fluid back to the reservoir. They act as safety valves to protect the hydraulic system from overpressure conditions. Relief valves are typically normally closed and open only when pressure exceeds the set point, making them essential for system safety. Every hydraulic system should include at least one relief valve as a fundamental hydraulic control valve component.

Pressure Reducing Valves

These valves reduce the pressure in a specific branch of the hydraulic system to a lower, predetermined level while maintaining higher pressure in the main circuit. They are normally open and restrict flow when the downstream pressure reaches the set point. Pressure reducing valves are particularly useful when different components in a system require different operating pressures, allowing a single hydraulic control valve to manage multiple pressure zones.

Sequence Valves

Sequence valves control the order of operations in a hydraulic system by directing fluid to a second actuator only after the pressure required for the first actuator has been achieved. They open when upstream pressure reaches a preset level, allowing fluid to flow to another part of the system. This enables precise control of operational sequences, making them valuable in automated processes where specific operations must occur in a predetermined order.

Pressure Control Valve Performance Characteristics

Pressure Setting and Adjustment

Proper setting of pressure control valves is crucial for system performance and safety. The pressure setting determines the point at which the valve will actuate, and this must be carefully calibrated to match system requirements. Most pressure control valves feature an adjustment mechanism (typically a screw) that allows setting the actuation pressure within a specified range.

When adjusting a hydraulic control valve for pressure, it's essential to consider the maximum pressure rating of all system components, the required operating pressure for efficient performance, and any pressure margins needed for dynamic operations. Over-pressurization can lead to component failure, while under-pressurization may result in insufficient force or performance.

Modern pressure control valves often incorporate features such as pressure compensation, which maintains consistent pressure control regardless of flow rate variations, and tamper-resistant adjustments to prevent unauthorized changes to pressure settings. These advancements enhance the reliability and safety of hydraulic systems, ensuring that the pressure control valve operates precisely under varying conditions.

Flow control valves are designed to regulate the rate of transmission and hydraulic oil flow within a hydraulic system, directly influencing the speed of hydraulic actuators such as cylinders and motors. As an essential hydraulic control valve type, they allow operators to adjust the speed of movement for various hydraulic components, enabling precise control over machine operations.

The primary function of a flow control valve is to manage the volume of fluid passing through a specific section of the hydraulic circuit per unit of time. By controlling flow rate, these valves determine how quickly hydraulic actuators extend, retract, or rotate, which directly affects the overall performance and productivity of the machinery.

Flow control valves operate on various principles, including restricting flow passage, using pressure compensation to maintain consistent flow regardless of pressure variations, or incorporating adjustable orifices that can be modified to change flow rates. The selection of the appropriate flow control valve depends on factors such as required flow range, pressure drop characteristics, accuracy requirements, and whether the application requires adjustable or fixed flow rates.

Classification of Flow Control Valves

Fixed Flow Control Valves

These valves provide a constant, non-adjustable flow rate and are designed for applications where flow requirements remain consistent. They typically use fixed orifices of precisely calculated sizes to restrict flow to predetermined rates.

- Fixed orifice valves

- Non-adjustable needle valves

- Restrictor plates

Applications

Fixed flow control valves are commonly used in simple hydraulic systems where operational parameters don't change, or in specific circuit branches that require a constant flow rate regardless of system conditions. They offer cost-effective flow control in applications where adjustments are rarely needed.

Adjustable Flow Control Valves

These versatile valves allow operators to manually adjust flow rates as needed, providing flexibility for changing operational requirements. They feature adjustable orifices that can be modified using a knob, screw, or lever.

- Needle valves

- Gate valves

- Pressure-compensated flow control valves

- Flow dividers/combiners

Pressure-Compensated Valves

A specialized type of adjustable flow control valve that maintains a constant flow rate regardless of pressure variations in the system. This hydraulic control valve uses a pressure-sensing mechanism to adjust the orifice size automatically, compensating for pressure changes to maintain consistent flow.

Flow Control Valve Selection Considerations

Flow Range

The valve must accommodate the minimum and maximum flow rates required by the application.

Pressure Drop

Consider the pressure loss across the valve at different flow rates to ensure system efficiency.

Accuracy

The required precision of flow control, which varies by application from general to highly precise.

Response Time

How quickly the valve can adjust to flow rate changes, critical in dynamic applications.

Flow control valves are essential for optimizing hydraulic system performance, allowing for precise speed control of actuators and efficient operation of machinery. By regulating the volume of fluid delivered to different components, these valves ensure that each part of the system receives the appropriate flow rate to perform its function effectively.

In modern hydraulic systems, the integration of electronic controls with flow control valves has enabled more sophisticated flow management, including programmable flow profiles and closed-loop feedback control. This advancement has expanded the capabilities of the hydraulic control valve, allowing for greater precision, energy efficiency, and adaptability to changing operational requirements.

Proper installation and maintenance of flow control valves are essential for their reliable operation. This includes ensuring proper alignment, preventing contamination, and regular calibration to maintain accurate flow control. By selecting the right type of flow control valve and maintaining it properly, system operators can maximize efficiency, extend component life, and ensure safe and reliable operation of their hydraulic systems.

Proportional control valves represent a sophisticated category of hydraulic control valve that provides infinitely variable control of flow of hydraulic transmission oil, pressure, or direction in proportion to an electrical input signal. Unlike simple on/off or fixed-position valves, proportional valves offer precise, stepless control, enabling smooth and accurate operation of hydraulic systems.

These advanced valves bridge the gap between simple directional control valves and fully servo-controlled systems, offering many of the benefits of servo valves at a lower cost and with greater ruggedness. The proportional control valve uses an electrical input (typically 0-10V or 4-20mA) to position a spool or poppet within the valve, with the position directly proportional to the input signal strength.

Modern proportional valves often incorporate feedback mechanisms that continuously monitor the valve's actual position and adjust the electrical input accordingly to maintain precise control. This closed-loop control system ensures high accuracy and repeatability, even under varying operating conditions.

Components and Operation of Proportional Valves

Electrical Interface

Converts the input electrical signal (analog or digital) into a force that positions the valve spool. This typically includes a proportional solenoid or torque motor that generates a force proportional to the input current.

Mechanical Actuator

Translates the electrical force into precise mechanical movement of the valve spool or poppet. This may include springs, levers, or hydraulic amplifiers that provide the necessary force and movement control.

Feedback System

Monitors the actual position of the valve element and provides feedback to the control electronics. This allows for closed-loop control and compensation for factors like friction, pressure, and temperature changes.

Types of Proportional Control Valves

| Valve Type | Function | Key Applications | Advantages |

|---|---|---|---|

| Proportional Directional Valves | Control flow direction and rate proportionally | Material handling, machine tools, robotics | Smooth acceleration/deceleration, precise positioning |

| Proportional Pressure Valves | Regulate pressure in proportion to input signal | Presses, clamping systems, tension control | Controllable force, pressure profiling capability |

| Proportional Flow Valves | Control flow rate with high precision | Injection molding, speed control, synchronization | Accurate speed control, flow profiling |

| Proportional Cartridge Valves | Integrate proportional control in cartridge design | Mobile equipment, custom manifold systems | Compact design, high flow capacity |

Advantages of Proportional Control Valves

-

Precise control over hydraulic parameters, enabling complex motion profiles and operations

-

Smooth operation with reduced shock and vibration compared to on/off valves

-

Integration capability with electronic control systems for automated operation

-

Energy efficiency through precise control of only required flow and pressure

-

Reduced component wear due to smoother transitions and controlled movements

-

Increased productivity through optimized machine performance and cycle times

The proportional control valve has revolutionized hydraulic system design, enabling levels of precision and automation that were previously difficult or expensive to achieve. As electronic control systems continue to advance, the capabilities of proportional hydraulic control valves will expand further, offering even greater performance, efficiency, and integration possibilities for modern hydraulic systems.

Cartridge valves and manifold systems represent a modular approach to hydraulic control, offering compact, efficient, and customizable solutions for complex hydraulic circuits like hydraulic gearbox. A cartridge valve is a compact, self-contained hydraulic control valve that mounts into a manifold block, which contains the flow passages and connections between valves.

This modular design provides numerous advantages over traditional discrete valve systems, including reduced space requirements, lower pressure drops, fewer potential leak points, and easier maintenance. Cartridge valves can be combined in manifold systems to create custom hydraulic circuits tailored to specific application requirements.

The cartridge valve itself consists of a valve element (spool, poppet, or seat) contained within a cylindrical housing that fits into a bored cavity in the manifold block. The manifold block is precision-machined with internal passages that connect the various cartridge valves, creating the complete hydraulic circuit without external piping.

Types of Cartridge Valves

Directional Control Cartridges

These cartridge valves control the direction of fluid flow, including check valves, shuttle valves, and directional spool valves. They provide the same functionality as their discrete counterparts but in a compact cartridge format.

Pressure Control Cartridges

These include relief, reducing, sequence, and counterbalance valves in cartridge form. They regulate system pressure precisely while maintaining the compact design advantages of cartridge systems.

Flow Control Cartridges

These cartridge valves manage flow rates within the hydraulic system, including fixed and adjustable flow control valves, flow dividers, and priority valves, all in compact designs.

Manifold Systems

The manifold block serves as the foundation for cartridge valve systems, providing the structural support and internal flow passages that connect the various cartridge valves. Manifolds can be constructed from various materials, including steel, aluminum, and cast iron, depending on pressure requirements, flow rates, and environmental conditions.

Manifold Design Considerations

- Internal flow passage sizing to minimize pressure drop

- Material selection based on pressure rating and compatibility

- Mounting provisions for cartridge valves and external connections

- Accessibility for maintenance and valve replacement

- Integration with system components and mounting surfaces

Advantages of Manifold Systems

- Compact design reduces overall system footprint

- Fewer leak points compared to piped systems

- Lower pressure drops improve system efficiency

- Customizable configurations for specific applications

- Easier maintenance with modular cartridge replacement

Manifold systems can be designed as standard off-the-shelf components for common applications or custom-engineered for specific hydraulic control requirements. The modular nature of cartridge valves and manifolds allows for easy modification or expansion of hydraulic systems as needs evolve, providing a flexible solution that can adapt to changing operational requirements.

Applications of Cartridge and Manifold Systems

Cartridge valves and manifold systems are used across a wide range of industries and applications where compact, efficient hydraulic control is required. Their modular design makes them particularly suitable for applications with space constraints or complex hydraulic circuits that would be difficult to implement with traditional valve arrangements.

Mobile Equipment

Excavators, loaders, and agricultural machinery benefit from the compact design and high power density.

Industrial Machinery

Injection molding machines, presses, and automated production lines utilize their precise control.

Marine Applications

Shipboard systems benefit from their compact design and resistance to vibration.

Aerospace

Aircraft systems utilize their lightweight design and reliable performance.

The cartridge valve and manifold approach represents a significant advancement in hydraulic control valve technology, offering a versatile, efficient, and compact solution for modern hydraulic systems. As industries continue to demand more from their hydraulic systems in terms of performance, efficiency, and space utilization, the role of cartridge and manifold valve systems will continue to grow in importance.

The Future of Hydraulic Control Valves

The hydraulic control valve continues to evolve alongside advancements in materials science, electronics, and control systems. Modern hydraulic control valves are becoming smarter, more efficient, and more integrated with electronic control systems, enabling unprecedented levels of precision, energy efficiency, and connectivity.

Future developments in hydraulic control valve technology will likely focus on enhancing integration with Industry 4.0 initiatives, incorporating sensor technology for condition monitoring and predictive maintenance, and improving energy efficiency through advanced design and materials. The ongoing miniaturization of components while maintaining or increasing performance will also drive innovation in hydraulic control valve design.Optical Transceiver.

As industries continue to demand more efficient, precise, and reliable hydraulic systems, the hydraulic control valve will remain a critical component, adapting and evolving to meet the changing needs of modern machinery and equipment. Understanding the various types of hydraulic control valves, their functions, and applications is essential for anyone involved in the design, operation, or maintenance of hydraulic systems, ensuring optimal performance, safety, and efficiency.Electronic shelf labels.