Section 1: Hydraulic System Design Steps and Methods

Understanding concepts like what is a hydro transmission is key when designing an efficient hydraulic system, which requires a systematic approach that combines engineering principles with practical considerations. The process involves several critical stages, each building upon the previous one to ensure the final system meets all performance requirements while optimizing reliability and cost-effectiveness. Proper Hydraulic calculations are essential throughout this process to validate design decisions and predict system behavior.

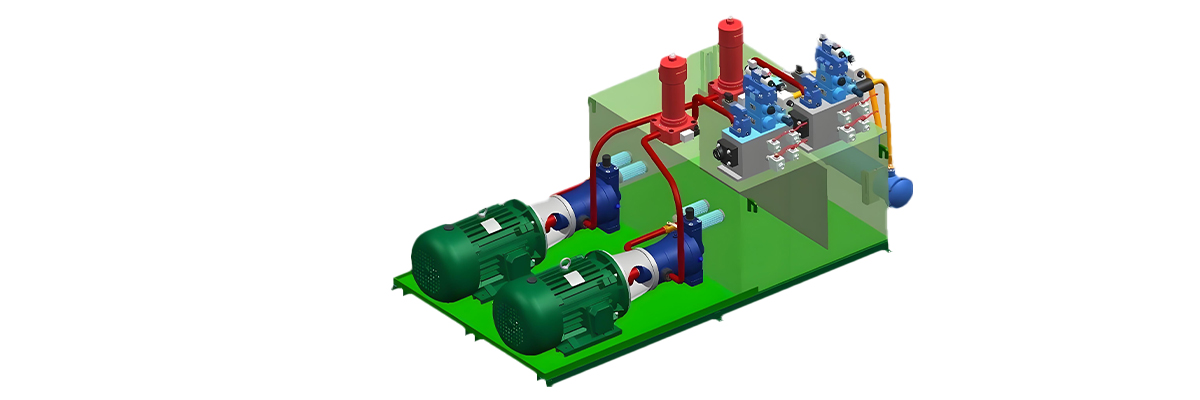

Figure 1: Comprehensive hydraulic system design workflow

The foundation of any successful hydraulic system design is a clear understanding of the requirements. This phase involves close collaboration with the end-users to define:

- Required actuator force or torque output

- Speed of movement for all actuators

- Operating pressure ranges

- Cycle times and duty cycles

- Environmental conditions (temperature, humidity, contamination risks)

- Space constraints and installation limitations

- Safety requirements and standards compliance

- Energy efficiency targets

Thorough documentation of these requirements provides the framework for subsequent design decisions and Hydraulic calculations. This stage often involves creating detailed use-case scenarios and performance specifications that will guide the entire design process.

Based on the defined requirements, the next step involves selecting suitable hydraulic actuators – either cylinders for linear motion or motors for rotational motion. This selection process requires careful Hydraulic calculations to ensure the chosen actuators can deliver the required force, torque, and speed.

For Hydraulic Cylinders:

- Bore diameter calculation based on force requirements

- Rod diameter selection for buckling resistance

- Stroke length determination based on movement requirements

- Mounting style selection for load conditions

For Hydraulic Motors:

- Displacement calculation based on torque requirements

- Speed rating verification

- Mounting configuration and shaft requirements

- Efficiency considerations for power consumption

Actuator selection directly impacts the subsequent Hydraulic calculations for pump sizing, valve selection, and overall system pressure requirements. It's critical to account for efficiency losses and safety factors during this selection process.

Establishing the operating pressure and required flow rate is a critical stage that involves detailed Hydraulic calculations. System pressure directly influences component size, weight, and cost, while flow rate determines the speed of actuator movement.

Figure 2: Pressure-flow relationship in hydraulic systems

Pressure requirements are typically determined by the force needs of the actuators, calculated using the formula:

Flow rate calculations depend on the required actuator speed and size. For cylinders, flow rate is determined by the piston area and desired velocity, while for motors, it's based on displacement and rotational speed. These Hydraulic calculations must account for all actuators that might operate simultaneously to determine the total system flow requirements.

The hydraulic pump serves as the heart of the system, converting mechanical energy into hydraulic energy. Proper pump selection is critical and depends on the results of previous Hydraulic calculations regarding pressure and flow requirements.

| Pump Type | Pressure Range | Efficiency | Typical Applications |

|---|---|---|---|

| Gear Pump | Up to 210 bar | 70-85% | Low to medium pressure systems |

| Vane Pump | Up to 175 bar | 75-90% | Medium pressure, steady flow |

| Piston Pump | Up to 420 bar | 85-95% | High pressure, variable flow |

Pump sizing requires calculating the total flow demand, including any necessary reserves for future expansion or system losses. The pump's displacement and drive power requirements are determined through Hydraulic calculations that consider system pressure, flow rate, and overall efficiency.

Hydraulic control valves regulate pressure, direction, and flow rate within the system. The selection process involves matching valve specifications to the system's pressure and flow requirements determined through previous Hydraulic calculations.

Directional Valves

Control actuator movement direction

Flow Control Valves

Regulate actuator speed

Pressure Control Valves

Maintain system pressure limits

Valve selection must consider factors such as response time, pressure drop, flow capacity, and compatibility with the fluid type. Properly sized valves minimize energy losses while ensuring precise control, making them a critical component in efficient system design. The Hydraulic calculations for valve sizing focus on flow coefficients (Cv) and pressure drop characteristics to ensure optimal performance.

The hydraulic circuit design phase involves arranging all components into a coherent system that meets the performance requirements. This stage typically begins with a detailed schematic diagram using standard ISO or ANSI symbols to represent each component and its connections.

Figure 3: Example hydraulic circuit schematic

Circuit design must consider:

- Component arrangement for efficient operation and maintenance

- Pressure losses in lines and fittings

- Flow path optimization to minimize energy losses

- Safety features such as relief valves and bypass circuits

- System protection against contamination and overheating

- Emergency shutdown capabilities

During this phase, additional Hydraulic calculations verify pressure drops through the circuit, ensuring that component sizing remains appropriate when integrated into the complete system. The circuit design often undergoes several iterations to optimize performance, reliability, and cost-effectiveness.

Proper sizing of hydraulic lines, hoses, and fittings is essential to minimize pressure losses, ensure efficient flow, and prevent excessive fluid velocity that can cause erosion and noise. This stage involves detailed Hydraulic calculations to determine the optimal diameter for each section of the circuit.

Key Considerations for Line Sizing:

Fluid Velocity: Typically limited to 2-4 m/s for pressure lines, 0.5-1 m/s for suction lines

Pressure Drop: Should be minimized to avoid energy loss and inefficiency

Material Selection: Based on pressure rating and environmental factors

Bend Radius: For hoses to prevent flow restriction and premature failure

The Hydraulic calculations for line sizing involve using the continuity equation to relate flow rate to fluid velocity and cross-sectional area. For a given flow rate, smaller diameter lines create higher velocities, increasing pressure drop and system noise. Larger diameter lines reduce velocity but increase cost and space requirements, creating a design trade-off that must be carefully balanced.

Hydraulic fluid selection is critical for system performance, as it affects viscosity, lubrication, corrosion resistance, and thermal properties. The reservoir design must accommodate the fluid volume while providing proper cooling, contamination control, and air separation.

Fluid Selection Criteria:

- Viscosity characteristics at operating temperatures

- Pour point and flash point for temperature extremes

- Anti-wear and anti-corrosion properties

- Compatibility with system materials

- Environmental considerations

Reservoir Design Factors:

- Volume (typically 3-5 times pump flow per minute)

- Cooling capacity and heat dissipation

- Baffle design for fluid conditioning

- Filtration and contamination control

- Access for maintenance and fluid sampling

Hydraulic calculations for fluid selection involve determining the appropriate viscosity grade based on operating temperature ranges and system pressure. Reservoir sizing calculations consider the total system volume, flow rate, and heat rejection requirements to prevent overheating during operation. Proper fluid and reservoir selection significantly impacts system efficiency, component life, and maintenance requirements.

Before finalizing the design, a comprehensive performance analysis is conducted to verify that all requirements are met. This stage involves advanced Hydraulic calculations and often includes computer simulation to model system behavior under various operating conditions.

Figure 4: Performance analysis graph showing pressure vs. flow characteristics

Performance analysis evaluates:

- System efficiency under various load conditions

- Pressure and flow stability during operation

- Response times for actuator movements

- Heat generation and thermal equilibrium

- Energy consumption and power requirements

- Component stress levels and service life predictions

The results of this analysis often lead to design refinements, with additional Hydraulic calculations performed to optimize specific components or circuit configurations. This iterative process continues until the system meets all performance criteria while balancing efficiency, reliability, and cost considerations.

The final stage of the design process involves comprehensive documentation and validation testing. Documentation includes detailed schematics, component lists, assembly drawings, and maintenance procedures, along with all Hydraulic calculations performed during the design process.

Validation Testing Procedures:

- Component testing to verify specifications

- System assembly verification and pressure testing

- No-load operation to check basic functionality

- Full-load testing under design operating conditions

- Cycle testing to evaluate durability and reliability

- Performance measurement against design criteria

- Safety and emergency function verification

Testing often reveals minor issues that require adjustments, with additional Hydraulic calculations performed to validate any design modifications. The documentation package serves as a valuable reference for installation, operation, and maintenance personnel, ensuring proper system care throughout its service life. Successful validation confirms that the hydraulic system meets all design requirements and is ready for deployment.

Section 2: Hydraulic System Design Calculation Examples

Practical examples of Hydraulic calculations help illustrate the application of design principles to real-world scenarios. The following examples demonstrate the step-by-step calculation process for common hydro mechanical hydraulic system components, showing how theoretical concepts translate into practical design decisions. These examples cover key calculations that form the foundation of hydraulic system design, from actuator sizing to power requirements.

Figure 5: Systematic approach to hydraulic system calculations

Cylinder Sizing Calculation

Determining piston and rod dimensions

This example demonstrates the Hydraulic calculations required to size a hydraulic cylinder for a specific application. Let's assume we need to design a cylinder to lift a 50,000 N load with a maximum system pressure of 200 bar.

Given Parameters:

- Required force (F) = 50,000 N

- System pressure (P) = 200 bar = 20,000,000 Pa (since 1 bar = 100,000 Pa)

- Safety factor = 1.5 (standard for static loads)

Calculation Steps:

-

Calculate the required area with safety factor:

F_total = F × Safety factor = 50,000 N × 1.5 = 75,000 N

-

Determine the required piston area using the pressure formula:

A = F_total / P = 75,000 N / 20,000,000 Pa = 0.00375 m² = 37.5 cm²

-

Calculate the piston diameter from the area:

A = πd²/4 → d = √(4A/π) = √(4 × 37.5 / 3.1416) ≈ √47.75 ≈ 6.91 cm

-

Select the nearest standard cylinder size (70 mm bore)

-

Calculate rod diameter (typically 0.5-0.7× bore diameter for this application):

Rod diameter = 0.6 × 70 mm = 42 mm (standard size)

These Hydraulic calculations result in a 70 mm bore cylinder with a 42 mm rod, which can safely lift the 50,000 N load at 200 bar pressure. Additional calculations would be required to determine the appropriate stroke length based on the required lifting distance and to verify rod buckling resistance for the extended length.

Flow Rate Calculation

Determining required fluid flow for actuator speed

This example shows how to calculate the required flow rate to achieve a specific actuator speed, an essential part of Hydraulic calculations for system design. Using our 70 mm bore cylinder from the previous example, we want to determine the flow rate required to achieve a piston speed of 0.5 m/s.

Given Parameters:

- Cylinder bore diameter (d) = 70 mm = 0.07 m

- Desired piston speed (v) = 0.5 m/s

- Rod diameter = 42 mm (for return stroke calculation)

Calculation Steps:

-

Calculate the piston area:

A = πd²/4 = 3.1416 × (0.07)² / 4 = 3.1416 × 0.0049 / 4 ≈ 0.003848 m²

-

Calculate the extend stroke flow rate (Q_extend):

Q_extend = A × v = 0.003848 m² × 0.5 m/s = 0.001924 m³/s

Convert to liters per minute: 0.001924 × 60,000 = 115.44 L/min

-

Calculate the annulus area for return stroke:

A_annulus = A - π(rod diameter)²/4 = 0.003848 - 0.001385 ≈ 0.002463 m²

-

Calculate the return stroke flow rate (Q_return):

Q_return = A_annulus × v = 0.002463 × 0.5 = 0.0012315 m³/s = 73.89 L/min

These Hydraulic calculations show that we need 115.44 L/min to extend the cylinder at 0.5 m/s, while only 73.89 L/min is required for the return stroke due to the rod reducing the effective area. This difference is important when selecting directional control valves and designing circuit flow paths to ensure proper speed control in both directions.

Pump Power Calculation

Determining required motor power for the pump

Calculating the required power for a hydraulic pump is a critical aspect of Hydraulic calculations, ensuring the system has adequate power while avoiding oversizing. Using our previous example with a maximum flow rate of 115.44 L/min and system pressure of 200 bar, we'll determine the required pump power.

Given Parameters:

- Maximum flow rate (Q) = 115.44 L/min

- System pressure (P) = 200 bar

- Pump efficiency (η_pump) = 0.85 (typical for piston pumps)

- Motor efficiency (η_motor) = 0.90

Calculation Steps:

-

Convert flow rate to m³/s:

Q = 115.44 L/min ÷ 60,000 = 0.001924 m³/s

-

Convert pressure to Pascals:

P = 200 bar × 100,000 = 20,000,000 Pa

-

Calculate hydraulic power requirement:

P_hydraulic = P × Q = 20,000,000 Pa × 0.001924 m³/s = 38,480 W = 38.48 kW

-

Calculate required shaft power (accounting for pump efficiency):

P_shaft = P_hydraulic / η_pump = 38.48 kW / 0.85 ≈ 45.27 kW

-

Calculate required motor power (accounting for motor efficiency):

P_motor = P_shaft / η_motor = 45.27 kW / 0.90 ≈ 50.3 kW

-

Select standard motor size: 55 kW (next available standard size)

These Hydraulic calculations indicate that a 55 kW motor is required to drive the pump, providing adequate power while accounting for efficiency losses. This calculation ensures the motor can handle the maximum load conditions without overheating or premature failure, while avoiding the inefficiency and added cost of an excessively oversized motor.

Pipe Sizing Calculation

Determining proper hydraulic line dimensions

Proper pipe sizing is essential to minimize pressure loss and ensure efficient operation. This example demonstrates the Hydraulic calculations required to size a pressure line for our system with a maximum flow rate of 115.44 L/min.

Given Parameters:

- Flow rate (Q) = 115.44 L/min

- Maximum recommended velocity (v) = 3 m/s (for pressure lines)

- Fluid kinematic viscosity (ν) = 40 cSt (typical for hydraulic oil at 40°C)

Calculation Steps:

-

Convert flow rate to m³/s:

Q = 115.44 L/min ÷ 60,000 = 0.001924 m³/s

-

Calculate required pipe cross-sectional area:

A = Q / v = 0.001924 m³/s / 3 m/s ≈ 0.000641 m²

-

Calculate required pipe diameter:

d = √(4A/π) = √(4 × 0.000641 / 3.1416) ≈ √0.000815 ≈ 0.0285 m = 28.5 mm

-

Select standard pipe size: 32 mm OD (28.5 mm ID)

-

Verify Reynolds number to confirm flow regime:

Re = (v × d) / ν = (3 m/s × 0.0285 m) / (40 × 10⁻⁶ m²/s) ≈ 2138

This indicates laminar flow (Re < 2000 is typically laminar), which is desirable for hydraulic systems.

These Hydraulic calculations show that a 32 mm outside diameter pipe with 28.5 mm inside diameter is appropriate for our system, maintaining fluid velocity within recommended limits. This sizing minimizes pressure drop while preventing excessive fluid velocity that could cause erosion, noise, and increased energy consumption. Additional calculations would be performed for return lines and suction lines, which have different velocity requirements.

Reservoir Sizing Calculation

Determining proper reservoir dimensions

The hydraulic reservoir serves multiple functions, including fluid storage, heat dissipation, and contamination settlement. This example demonstrates the Hydraulic calculations required to size an appropriate reservoir for our system.

Given Parameters:

- Pump flow rate (Q) = 115.44 L/min

- System volume (including cylinders, lines, etc.) = 200 L

- Heat load (from previous calculations) = 15 kW

- Maximum allowable temperature rise = 15°C

Calculation Steps:

-

Calculate minimum reservoir volume based on flow rate (3-5 times pump flow per minute):

V_min_flow = 4 × Q = 4 × 115.44 L/min = 461.76 L

-

Calculate required volume for heat dissipation:

V_heat = (3600 × Q_heat) / (ρ × c × ΔT)

Where: Q_heat = 15 kW, ρ = 870 kg/m³, c = 1.8 kJ/kg°C, ΔT = 15°C

V_heat = (3600 × 15) / (870 × 1.8 × 15) ≈ 54,000 / 23,490 ≈ 2.3 m³ = 2300 L

-

Calculate total system volume requirement:

V_total = V_heat + system volume = 2300 L + 200 L = 2500 L

-

Determine reservoir dimensions (typically length:width:height = 3:2:1):

Volume = l × w × h = 3x × 2x × x = 6x³ = 2.5 m³ → x³ = 0.4167 → x ≈ 0.747 m

Length = 3x ≈ 2.24 m, Width = 2x ≈ 1.49 m, Height ≈ 0.75 m

These Hydraulic calculations indicate that a 2500 L reservoir with dimensions approximately 2.24m × 1.49m × 0.75m is required for adequate heat dissipation and fluid storage. This size ensures proper fluid conditioning, allowing contaminants to settle and air to separate from the fluid while providing sufficient surface area for heat transfer. In practice, additional cooling might be considered to reduce reservoir size if space is limited.Optical Transceiver.

Pressure Drop Calculation

Calculating pressure loss in hydraulic lines

Calculating pressure drop in hydraulic lines is essential to ensure adequate pressure reaches actuators and to minimize energy losses. This example demonstrates the Hydraulic calculations for pressure drop in our 32 mm diameter pressure line, assuming a length of 10 meters.

Given Parameters:

- Pipe diameter (d) = 28.5 mm = 0.0285 m (inside diameter)

- Pipe length (L) = 10 m

- Flow rate (Q) = 115.44 L/min = 0.001924 m³/s

- Fluid dynamic viscosity (μ) = 0.035 Pa·s (at operating temperature)

- Fluid density (ρ) = 870 kg/m³

Calculation Steps:

-

Calculate fluid velocity (already determined in pipe sizing):

v = 3 m/s

-

Verify Reynolds number (laminar flow as previously determined):

Re = (ρ × v × d) / μ = (870 × 3 × 0.0285) / 0.035 ≈ 74.5 / 0.035 ≈ 2129

-

Calculate pressure drop using Poiseuille's law for laminar flow:

ΔP = (32 × μ × L × v) / d²

ΔP = (32 × 0.035 × 10 × 3) / (0.0285)² ≈ 33.6 / 0.000812 ≈ 41,380 Pa ≈ 0.414 bar

-

Add additional pressure drop for fittings (typically 20% of straight pipe loss):

ΔP_total = 0.414 bar × 1.20 ≈ 0.497 bar

These Hydraulic calculations show a total pressure drop of approximately 0.5 bar in the 10-meter pressure line, which is acceptable for our system operating at 200 bar. This relatively small pressure loss ensures efficient operation while confirming our pipe sizing is appropriate. For longer lines or higher flow rates, more significant pressure drops might require larger pipe sizes or pressure compensation in the system design. Related Lithium Battery Manufacturing.