Introduction to Hydraulic Transmission

Hydraulic transmission is a technology that uses pressurized fluid to transmit power from one location to another. This method of power transmission has revolutionized various industries by providing efficient, flexible, and powerful solutions for moving and controlling machinery. At the heart of these systems lies the proper management of hydraulic and transmission fluid, which serves as both the power transmitter and the lubricant for system components.

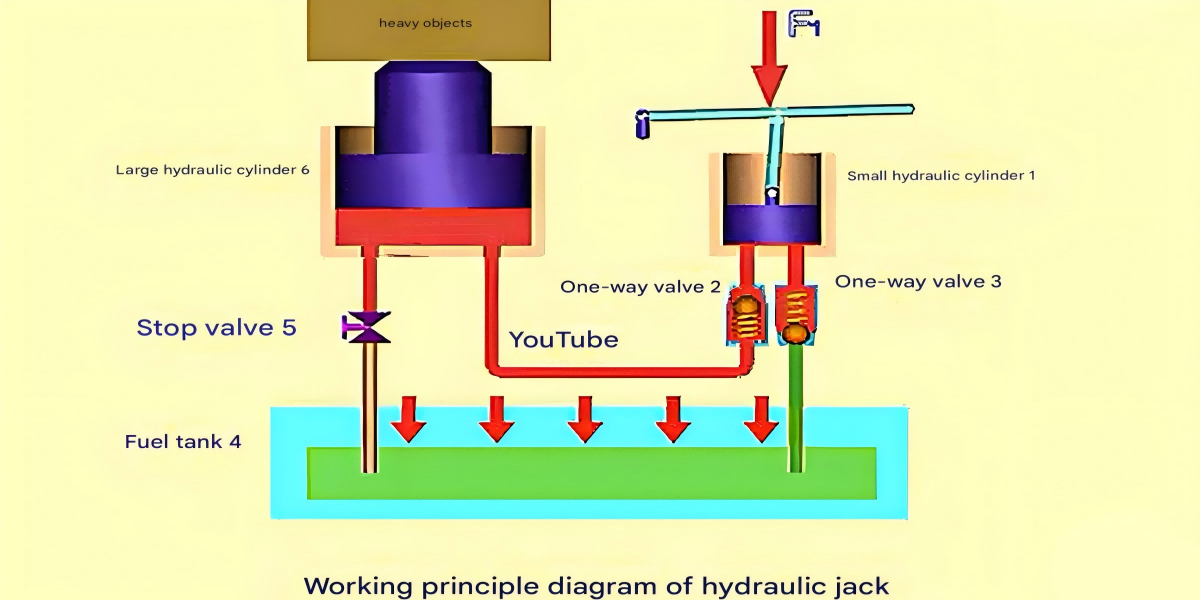

The basic principle of hydraulic transmission involves the use of a pump to convert mechanical energy into hydraulic energy, which is then transmitted through pipes or hoses to actuators (cylinders or motors) that convert the hydraulic energy back into mechanical energy. The hydraulic and transmission fluid plays a critical role in this process, ensuring smooth operation and preventing wear and tear on components.

This page explores the key advantages and disadvantages of hydraulic transmission systems compared to other power transmission methods such as mechanical, electrical, and pneumatic systems. Understanding these characteristics is essential for engineers, designers, and decision-makers when selecting the most appropriate transmission system for a specific application.

Main Advantages of Hydraulic Transmission

Hydraulic transmission offers numerous benefits over mechanical, electrical, and pneumatic transmission systems, making it the preferred choice in many industrial applications where precise control and power density are important factors.

Stepless Speed Regulation

Hydraulic transmission enables stepless speed regulation during operation, providing convenient speed adjustment with a relatively large range, typically reaching 100:1 to 2000:1. This level of flexibility allows for precise control over machinery movement, adapting easily to changing operational requirements. The hydraulic and transmission fluid facilitates this by smoothly transferring power across varying pressure differentials, ensuring consistent performance at any speed within the system's range.

High Power Density

For the same power output, hydraulic transmission devices are smaller in size, lighter in weight, and more compact in structure. For example, the weight of a hydraulic motor is only 10%-20% of that of an electric motor with the same power, while being able to transmit larger forces or torques. This high power-to-weight ratio is particularly advantageous in mobile equipment where space and weight are critical considerations. Proper maintenance of hydraulic and transmission fluid ensures that these compact systems operate efficiently without excessive wear.

Smooth Operation

Hydraulic transmission systems operate with greater smoothness, featuring quick response, minimal impact, and the ability to start, brake, and reverse at high speeds. Hydraulic transmission devices can achieve reversal frequencies of up to 500 cycles per minute for rotary motion and 400-1000 cycles per minute for reciprocating linear motion. The hydraulic and transmission fluid acts as a cushioning medium, absorbing shocks and vibrations that would otherwise be transmitted through the mechanical components, resulting in smoother operation and extended equipment life.

Easy Control and Automation

Hydraulic transmission systems are relatively simple to control and adjust, with convenient and labor-saving operation. They can be easily automated, and when used in conjunction with electrical controls, can achieve complex sequential operations and remote control. Modern hydraulic systems often incorporate sensors that monitor hydraulic and transmission fluid parameters, enabling precise control and diagnostics for optimal performance and efficiency.

Overload Protection

Hydraulic transmission systems can easily implement overload protection. If the system is overloaded, the hydraulic and transmission fluid can flow back to the tank through a relief valve, preventing damage to components. Additionally, because oil is used as the working medium, it provides automatic lubrication to moving parts, extending their service life and reducing maintenance requirements. This self-protective feature makes hydraulic systems more robust in harsh operating environments.

Standardization and Versatility

Hydraulic transmission components are easily standardized, serialized, and generalized, making them easier to design, manufacture, and promote. This standardization reduces costs and improves availability of replacement parts. The wide variety of standard components allows engineers to design custom systems for specific applications while maintaining compatibility with existing equipment. Proper selection of hydraulic and transmission fluid is simplified through these standards, ensuring optimal performance across different system configurations.

Flexible Motion and Arrangement

Hydraulic transmission easily enables both rotary and linear motions, with flexible arrangement of components. This flexibility in design allows hydraulic systems to be adapted to complex machinery layouts where mechanical transmission would be impractical. Pipes and hoses carrying hydraulic and transmission fluid can be routed around obstacles, giving designers greater freedom in equipment layout.

Additionally, in hydraulic transmission, the heat generated by power loss can be carried away by the flowing hydraulic and transmission fluid, preventing excessive temperature rise in local areas of the system. This thermal management capability is particularly important in high-power applications where heat buildup can cause premature component failure. The ability to dissipate heat through the fluid system eliminates the need for separate cooling systems in many applications, reducing complexity and cost.

Performance Comparison of Transmission Systems

Main Disadvantages of Hydraulic Transmission

While hydraulic transmission offers numerous advantages, it also presents certain limitations that must be considered when selecting a transmission system for a specific application.

Precision Limitations

Since liquid is used as the working medium, leakage can occur, and hydraulic and transmission fluid is compressible, making hydraulic systems unsuitable for applications requiring precise transmission ratios. Hydraulic transmission involves mechanical losses, pressure losses, and leakage losses, resulting in lower efficiency, which makes it unsuitable for long-distance transmission.

Environmental Sensitivity

Hydraulic transmission is sensitive to temperature and load changes, making it unsuitable for use in extremely low or high temperature environments. The hydraulic and transmission fluid properties can change significantly with temperature, affecting system performance. Additionally, hydraulic systems are sensitive to contamination, requiring careful maintenance to prevent particles from entering the system and causing damage.

Energy Source Limitations

Hydraulic transmission requires a separate energy source, such as a hydraulic pump station. Unlike electrical energy, hydraulic energy cannot be easily transmitted over long distances. This limits the flexibility of hydraulic systems in applications where remote operation is required without a local power source. The need to maintain adequate levels and quality of hydraulic and transmission fluid adds to the operational considerations.

Manufacturing Requirements

Hydraulic components require high manufacturing precision, which results in higher production costs. This necessitates specialized production facilities and expertise. The tight tolerances are necessary to minimize leakage of hydraulic and transmission fluid, which could compromise system efficiency and performance. The precision requirements also extend to system assembly, requiring trained technicians for proper installation.

Maintenance and Troubleshooting Challenges

When faults occur in hydraulic transmission systems, identifying the cause can be challenging, and troubleshooting often requires specialized knowledge and diagnostic equipment. The complexity of hydraulic circuits, combined with the invisibility of the hydraulic and transmission fluid flow within the system, makes it difficult to visually identify problems.

Maintenance procedures for hydraulic systems are also more specialized compared to mechanical systems, often requiring trained personnel to handle tasks such as fluid analysis, filter replacement, and system flushing. Proper maintenance of hydraulic and transmission fluid is critical to prevent system degradation and failure, adding to the operational complexity.

Applications of Hydraulic Transmission

Despite its limitations, hydraulic transmission offers significant advantages that make it the preferred choice in numerous industrial applications across various sectors.

Construction Machinery

Hydraulic systems are widely used in excavators, bulldozers, cranes, and loaders. These applications benefit from the high power density and precise control offered by hydraulic transmission, with specially formulated hydraulic and transmission fluid designed to withstand the high pressures and heavy loads encountered in construction environments.

Agricultural Equipment

Tractors, harvesters, and other agricultural machinery rely heavily on hydraulic systems for functions like lifting, tilting, and powering attachments. The ability to transmit large forces through compact components makes hydraulic transmission ideal for these applications, with hydraulic and transmission fluid designed to resist contamination from agricultural environments.

Industrial Machinery

In manufacturing, hydraulic systems power presses, injection molding machines, and material handling equipment. The precise control and high force capabilities of hydraulic transmission are essential in these applications, with carefully maintained hydraulic and transmission fluid ensuring consistent performance and product quality.

Automotive Industry

While mechanical and electrical systems dominate in passenger vehicles, hydraulic systems are still used in braking systems, power steering, and convertible tops. Heavy-duty vehicles like trucks and buses rely extensively on hydraulic transmission for various functions, with specialized hydraulic and transmission fluid formulations meeting automotive performance standards.

Aerospace

Aircraft use hydraulic systems for landing gear, flight control surfaces, and braking systems. The high power-to-weight ratio and reliability of hydraulic transmission make it ideal for aerospace applications, where specialized hydraulic and transmission fluid must perform under extreme temperature and pressure conditions.

Marine Applications

Ships and offshore platforms utilize hydraulic systems for steering, cargo handling, and winches. Hydraulic transmission provides the necessary power for these heavy-duty applications while withstanding the harsh marine environment. Specialized hydraulic and transmission fluid formulations resist water contamination and corrosion in these challenging conditions.

Advancements in Hydraulic Transmission Technology

Overall, hydraulic transmission offers more advantages than disadvantages, and its limitations are being gradually overcome with advancements in production technology. Research and development efforts continue to address the challenges of hydraulic systems, including improvements in efficiency, reduction of leakage, and development of more environmentally friendly hydraulic and transmission fluid formulations.

Modern hydraulic systems incorporate electronic controls for enhanced precision and efficiency, while new materials and manufacturing techniques are reducing costs and improving reliability. The development of biodegradable hydraulic and transmission fluid options is addressing environmental concerns associated with fluid leakage.

As a result, hydraulic transmission continues to find widespread applications in various sectors of the national economy and holds promising prospects in modern production. The ongoing evolution of hydraulic technology, including innovations in hydraulic and transmission fluid science, ensures that hydraulic systems will remain a vital component of industrial power transmission for decades to come.

Conclusion

Hydraulic transmission systems offer a unique combination of power, precision, and flexibility that makes them indispensable in numerous industrial applications. While they present certain challenges related to efficiency, maintenance, and environmental sensitivity, ongoing technological advancements continue to improve their performance and reliability. Proper selection and maintenance of hydraulic and transmission fluid remain critical factors in ensuring optimal system performance and longevity. As industries continue to demand more efficient and versatile power transmission solutions, hydraulic systems will undoubtedly play a key role in meeting these needs.

Learn more