Hydraulic Transmissions: A Revolutionary Technology

Compared to mechanical transmissions, hydraulic transmissions represent a relatively new technology in the broader field of power transmissions. While mechanical transmissions have a long history dating back to ancient civilizations, hydraulic transmissions emerged much later as a sophisticated means of power transfer and control.

The fundamental principle that enables hydraulic transmissions lies in the ability to transmit force through confined fluid, allowing for flexible, powerful, and precise control of machinery. This unique characteristic has made hydraulic transmissions indispensable in countless industrial applications, revolutionizing how work is performed across various sectors.

Today, hydraulic transmissions continue to evolve, incorporating advanced technologies and materials to meet the ever-increasing demands for efficiency, power, and reliability in modern machinery.

Historical Foundations of Hydraulic Transmissions

Pascal's Principle

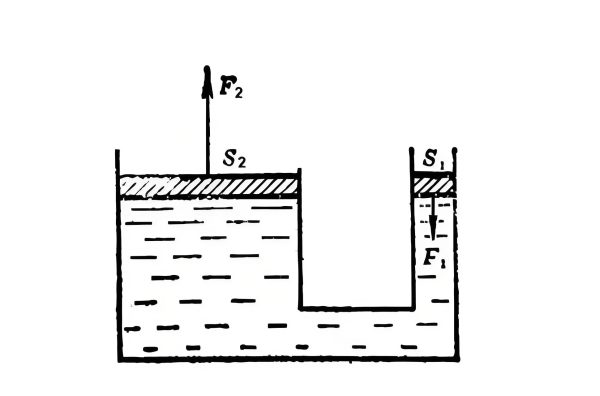

The theoretical foundation for hydraulic transmissions was established when Blaise Pascal formulated his law of hydrostatics, stating that pressure exerted anywhere in a confined incompressible fluid is transmitted equally in all directions.

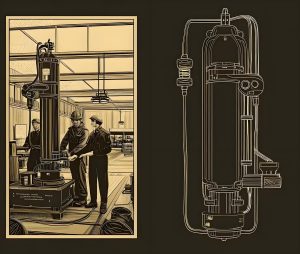

First Water Press

Joseph Bramah developed the first practical water press in England, marking the first major application of hydraulic principles in industrial machinery and laying groundwork for future hydraulic transmissions.

Oil Replaces Water

A significant advancement in hydraulic transmissions occurred when engineers began using oil instead of water as the working medium, dramatically improving lubrication, sealing, and overall performance of hydraulic systems.

The Rise of Petroleum and Hydraulic Transmissions

The widespread adoption and advancement of hydraulic transmissions were greatly facilitated by the rise and rapid development of the petroleum industry in the 19th century. This industry not only provided the necessary working fluids for hydraulic systems but also created a demand for heavy machinery that could benefit from the advantages of hydraulic transmissions.

As petroleum exploration and refining techniques improved, the quality and availability of hydraulic oils increased, making hydraulic transmissions more reliable and economically viable. This symbiotic relationship between the petroleum industry and hydraulic technology drove innovation in both fields, creating a foundation for the modern hydraulic transmissions we rely on today.

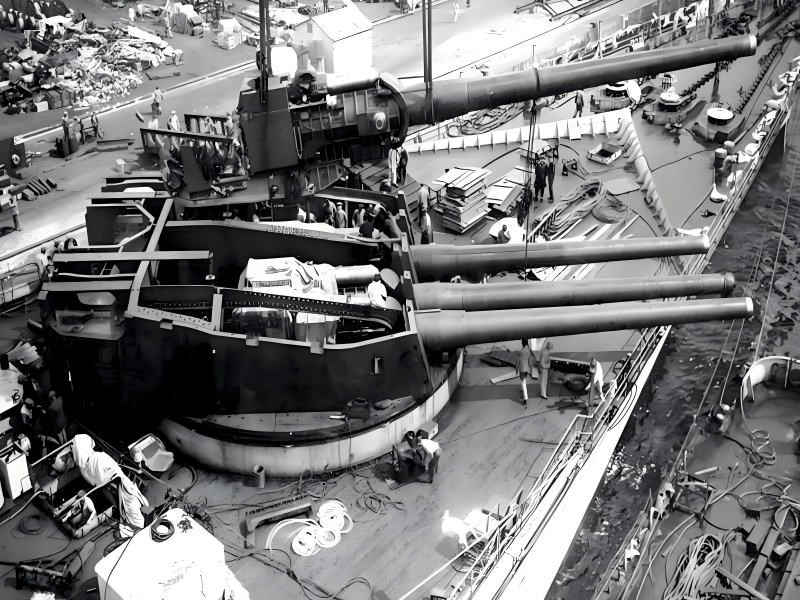

Early Applications of Hydraulic Transmissions

One of the first successful applications of hydraulic transmissions was in naval artillery systems, specifically in turret positioning mechanisms on warships. These early hydraulic transmissions provided the precise control and significant power required to rotate heavy gun turrets, a task that was previously challenging with mechanical transmissions alone.

The advantages of these early hydraulic transmissions became immediately apparent: they offered smoother operation, better power-to-weight ratio, and more precise control compared to mechanical alternatives. These benefits quickly led to experimentation with hydraulic transmissions in other military applications, from aircraft control systems to armored vehicles.

The reliability and performance of these early hydraulic systems demonstrated their potential beyond military use, paving the way for their eventual adoption in civilian applications.

Hydraulic Transmissions During and After World War II

WWII: Catalyst for Innovation

World War II proved to be a major catalyst for advancements in hydraulic transmissions. Military applications demanded hydraulic systems that could provide rapid response, high precision, and significant power—requirements that pushed engineers to develop more sophisticated hydraulic transmissions.

Aircraft, tanks, ships, and other military equipment incorporated increasingly advanced hydraulic transmissions to meet the rigorous demands of warfare. These applications required hydraulic systems that could operate reliably under extreme conditions, leading to improvements in component design, materials, and fluid technology.

The wartime emphasis on performance and reliability accelerated the development of hydraulic transmissions by leaps and bounds, creating technological breakthroughs that would have taken decades under normal circumstances.

Post-War Civilian Adoption

Following World War II, the advanced hydraulic technologies developed for military applications quickly found their way into civilian industries. This transition marked a new era for hydraulic transmissions, as they began to revolutionize manufacturing, construction, agriculture, and transportation.

Factories embraced hydraulic transmissions for automated machinery, enabling more precise control of production processes. Construction equipment manufacturers integrated hydraulic transmissions into excavators, cranes, and bulldozers, dramatically improving their performance and versatility compared to machines using mechanical transmissions.

The agricultural sector also benefited significantly from hydraulic transmissions, with tractors and harvesters gaining greater power and control. By the 1950s, hydraulic transmissions had become standard features in many types of industrial machinery, fundamentally changing how work was performed across countless industries.

Hydraulic Transmissions in the Modern Era (1960s-Present)

Technological Convergence

The 1960s marked a period of rapid advancement for hydraulic transmissions, driven by concurrent developments in atomic energy, space technology, and computing. These fields demanded increasingly sophisticated hydraulic systems, pushing the boundaries of what hydraulic transmissions could achieve.

Computer technology, in particular, revolutionized hydraulic transmissions by enabling precise control and monitoring, leading to the development of intelligent hydraulic systems that could adapt to changing conditions automatically.

Expanding Applications

As hydraulic technology advanced, hydraulic transmissions found their way into an ever-widening range of applications. From industrial robots to aerospace systems, from medical equipment to renewable energy installations, hydraulic transmissions proved their versatility and reliability across diverse sectors.

This period saw hydraulic transmissions becoming integral to modern life, often in ways that were invisible to the average person but essential to the functioning of contemporary society.

Current Trends in Hydraulic Transmissions Development

Performance Enhancement

Modern hydraulic transmissions are being developed to operate at higher speeds, pressures, and power levels while maintaining efficiency and reliability.

Noise Reduction

Significant research focuses on reducing noise levels in hydraulic transmissions, making them more suitable for urban and indoor applications.

Extended Lifespan

New materials and designs are increasing the service life of hydraulic transmissions, reducing maintenance requirements and overall costs.

Integration & Miniaturization

Hydraulic transmissions are becoming more compact and integrated, with higher power density and reduced space requirements.

Digital Control

Advanced electronic control systems are being integrated with hydraulic transmissions for improved precision, efficiency, and adaptability.

Eco-Friendly Solutions

Development of environmentally friendly hydraulic transmissions using water-based fluids and energy-efficient designs is accelerating.

Current Research Frontiers in Hydraulic Transmissions

Computer-Aided Testing (CAT)

Advanced CAT systems are revolutionizing how hydraulic transmissions are tested and validated, enabling more thorough analysis and faster development cycles while ensuring optimal performance and reliability.

Computer Direct Control (CDC)

CDC technologies are enabling more precise and responsive operation of hydraulic transmissions, with real-time adjustments that optimize performance based on operating conditions.

Mechatronics Integration

The fusion of mechanical, electronic, and software engineering is creating intelligent hydraulic transmissions that offer unprecedented levels of performance, efficiency, and adaptability.

Simulation & Optimization

Advanced computer modeling allows engineers to simulate and optimize hydraulic transmissions before physical prototypes are built, reducing development time and costs while improving performance.

Emerging Technologies

- Reliability engineering for extreme environments

- Water-based hydraulic transmissions for green manufacturing

- Advanced contamination control systems

- Self-diagnosing and self-healing hydraulic systems

- Energy recovery systems integrated with transmissions

- Additive manufacturing for custom hydraulic components

Development of Hydraulic Transmissions in China

Early Development (1950s-1970s)

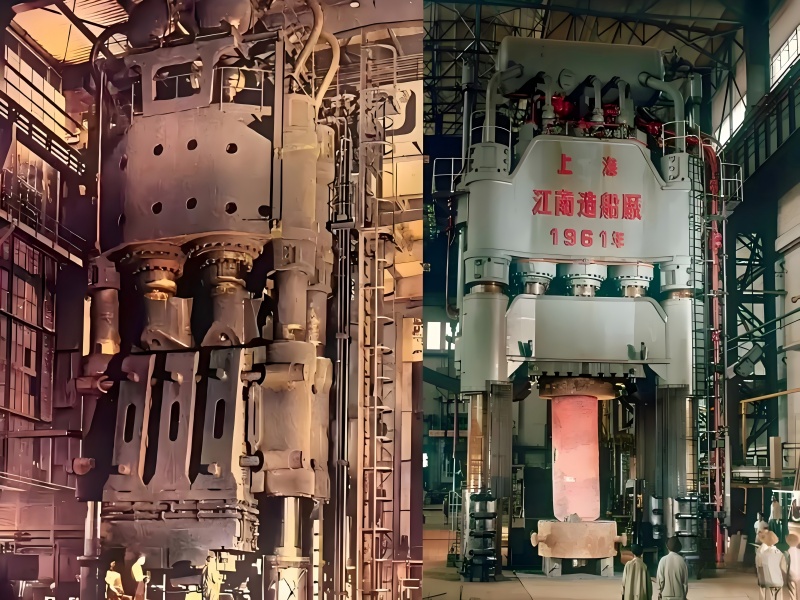

China's journey with hydraulic transmissions began in 1952, with early applications limited primarily to machine tools and forging equipment. These initial hydraulic systems were relatively simple but laid the foundation for future development.

Later, hydraulic transmissions found application in construction machinery, where their power and versatility proved particularly valuable. In 1964, China began importing hydraulic component production technologies from abroad while simultaneously developing its own domestic hydraulic products.

This dual approach of technology importation and domestic development established the framework for China's hydraulic industry, building both technical capabilities and manufacturing infrastructure.

Modern Development and Current Status

The 1980s marked a significant turning point for China's hydraulic transmissions industry, with the introduction of advanced technologies and equipment from the United States, Japan, and Germany. This infusion of foreign expertise elevated China's hydraulic technology to new heights, enabling the production of more sophisticated and reliable hydraulic transmissions.

Today, China has developed a comprehensive range of standardized, serialized, and generalized hydraulic component products, covering nearly all types of hydraulic transmissions needed for industrial applications. This domestic production capability has reduced reliance on imports and positioned China as a major player in the global hydraulic transmissions market.

Chinese manufacturers have focused on absorbing and adapting foreign advanced hydraulic technologies while vigorously developing new domestic hydraulic products. Significant emphasis has been placed on improving product quality and reliability, as well as researching and applying new technologies.

The industry has actively adopted new international standards, continuously adjusted product structures, and phased out outdated hydraulic components with poor performance. This commitment to quality and innovation has enabled China's hydraulic transmissions to compete effectively in both domestic and international markets.

Future Outlook for Hydraulic Transmissions

As science and technology continue to advance—particularly in control technology and computer science—hydraulic传动与控制技术将进一步发展,应用范围将更加广泛。The integration of smart technologies with hydraulic transmissions promises to create systems that are more efficient, more responsive, and more adaptable than ever before.

Technological Convergence

The future of hydraulic transmissions lies in their integration with other advanced technologies. Artificial intelligence, for example, will enable hydraulic systems to learn from operating experiences and optimize their performance automatically. Similarly, the Internet of Things (IoT) will allow hydraulic transmissions to be monitored and maintained remotely, reducing downtime and improving efficiency.

These smart hydraulic transmissions will be able to communicate with other systems, enabling coordinated operation of complex machinery and processes. This level of integration will open new possibilities for automation and optimization across industries.

Expanding Applications

Future hydraulic transmissions will find applications in emerging fields such as renewable energy, where they will help optimize power generation from sources like wind and hydroelectric. In transportation, hydraulic hybrid systems will contribute to improved fuel efficiency and reduced emissions.

The medical industry will benefit from more precise and compact hydraulic transmissions for advanced surgical equipment, while space exploration will rely on specialized hydraulic systems capable of operating in extreme environments. As these new applications emerge, they will drive further innovation in hydraulic transmissions technology.