Hydraulic and Pneumatic Transmission

A Comprehensive Guide to Fluid Power Systems Engineering

Precision manufacturing technology support

Introduction to Hydraulic Transmission

Hydraulic transmission is a technology that uses pressurized hydraulic fluid to transfer power from one location to another. It plays a crucial role in modern industrial and mobile machinery, providing efficient and precise control of mechanical forces. This guide explores the principles, components, and applications of hydraulic and pneumatic systems in depth.

In hydraulic systems, power is transmitted through the use of an incompressible fluid, typically oil, which is forced through pipes and hoses by pumps. The fluid then acts on pistons or motors to produce mechanical motion. This method of power transmission offers several advantages over mechanical and electrical systems, including high power density, smooth operation, and precise control.

Industrial Applications

Hydraulic systems are widely used in manufacturing, construction, and material handling equipment due to their ability to generate high forces with compact components.

Mobile Equipment

From excavators to airplanes, hydraulic systems provide the power and control needed for heavy machinery and mobile applications.

Hydraulic Transmission

Chapter 1

Hydraulic Transmission OverviewHydraulic Transmission Overview

An introduction to the basic principles of hydraulic transmission, including Pascal's Law, system components, and the advantages of hydraulic systems over other power transmission methods.

Chapter 2

Hydraulic Oil & Fluid MechanicsHydraulic Oil and Fluid Mechanics

Covers the properties of hydraulic fluids, fluid flow characteristics, and the fundamentals of fluid mechanics as they apply to hydraulic systems.

Chapter 3

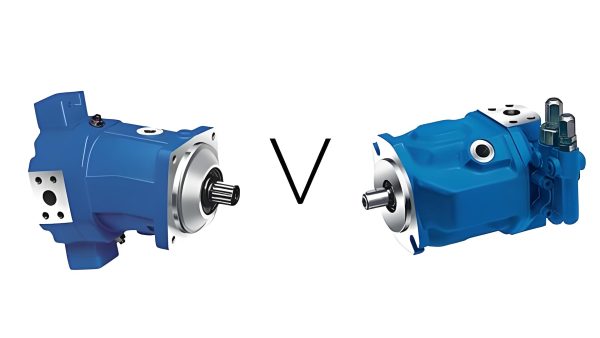

Hydraulic Pumps & MotorsHydraulic Pumps and Motors

Detailed analysis of different types of hydraulic pumps and motors, including gear, vane, and piston pumps, and their applications in hydraulic systems.

Chapter 4

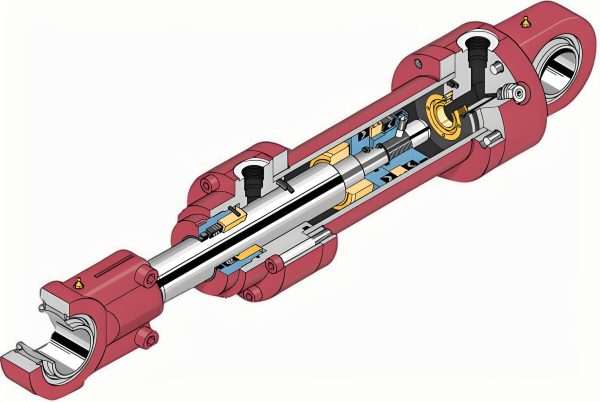

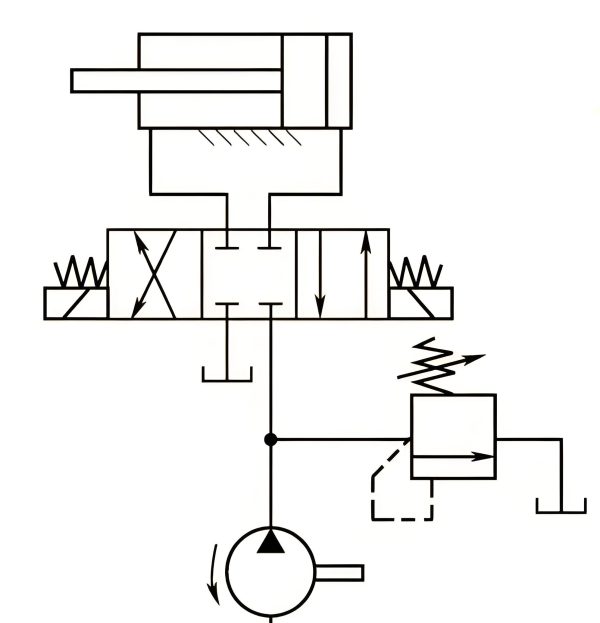

Hydraulic CylindersHydraulic Cylinders

Explores the design, operation, and selection of hydraulic cylinders, including single-acting and double-acting cylinders, and their role in converting hydraulic energy into linear motion.

Chapter 5

Hydraulic Control ValvesHydraulic Control Valves

An in-depth look at the various types of hydraulic control valves, including directional control valves, pressure control valves, and flow control valves, and their functions.

Chapter 6

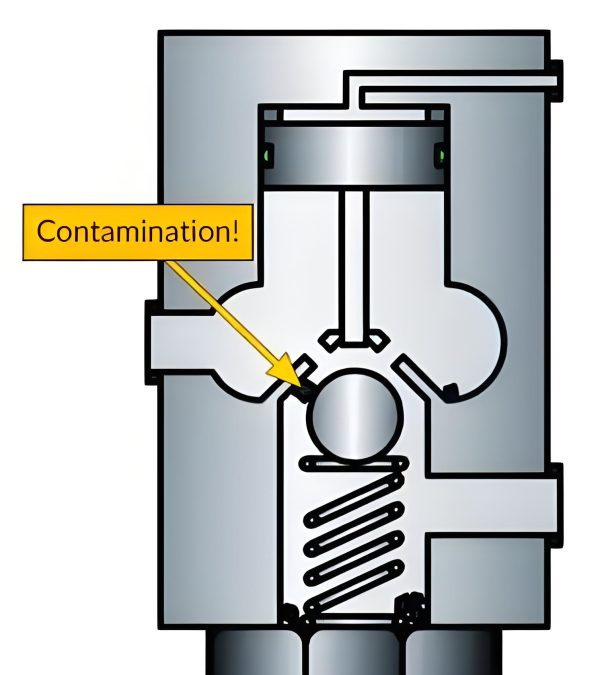

Hydraulic Auxiliary ComponentsHydraulic Auxiliary Components

Covers essential auxiliary components such as reservoirs, filters, accumulators, and heat exchangers, and their importance in maintaining system performance.

Chapter 7

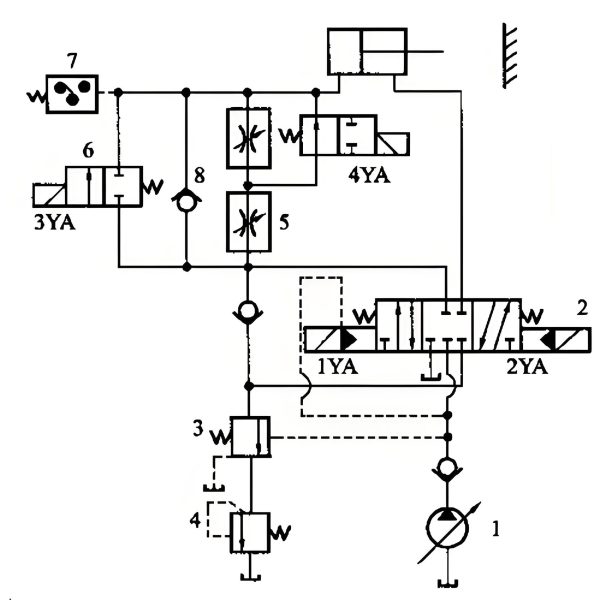

Hydraulic Basic CircuitsHydraulic Basic Circuits

Explains the design and analysis of Hydraulic circuit, focusing on its fundamental types including pressure control, flow control, and directional control circuits.

Chapter 8

Typical Hydraulic SystemsTypical Hydraulic Systems

Examines real-world examples of Hydraulic system applications, including those used in construction equipment, machine tools, and aerospace applications.

Chapter 9

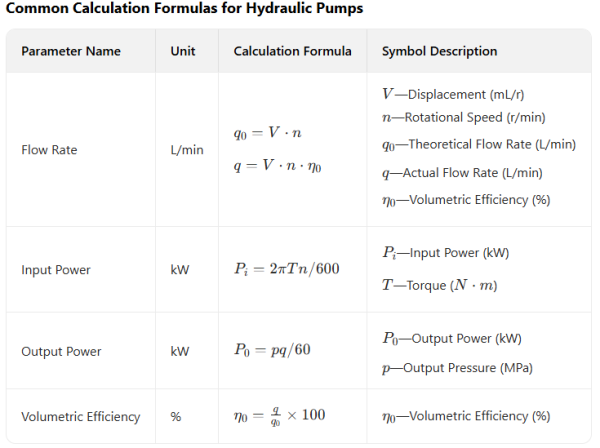

System Design & CalculationHydraulic System Design and Calculation

Provides a comprehensive guide to the design and Hydraulic calculations of hydraulic systems—including calculations for component selection, sizing verification, and performance analysis (e.g., pressure drop, flow rate, and power requirements).

Chapter 10

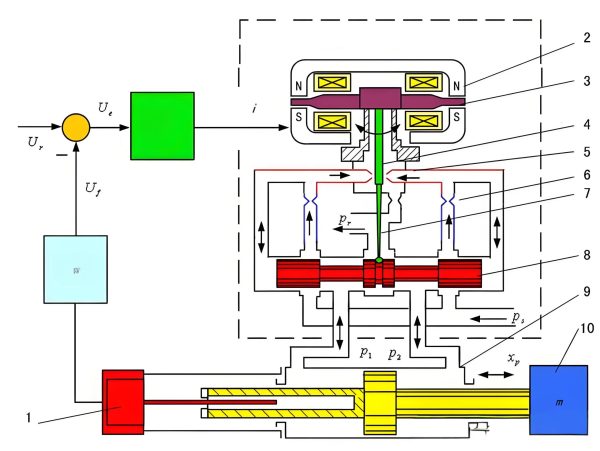

Hydraulic Servo SystemsHydraulic Servo Systems

Explores Hydraulic servo by delving into the principles and applications of its corresponding systems—systems that provide precise control of position, velocity, and force in response to an input signal.

Chapter 11

Pneumatic TransmissionPneumatic Transmission

An introduction to pneumatic systems, including their components (designed to generate, control, and transmit Air pressure, such as air tanks and regulators), operation principles (based on the use of Air pressure to drive actuators and execute mechanical actions), and applications in industrial automation and control.

Chapter 12

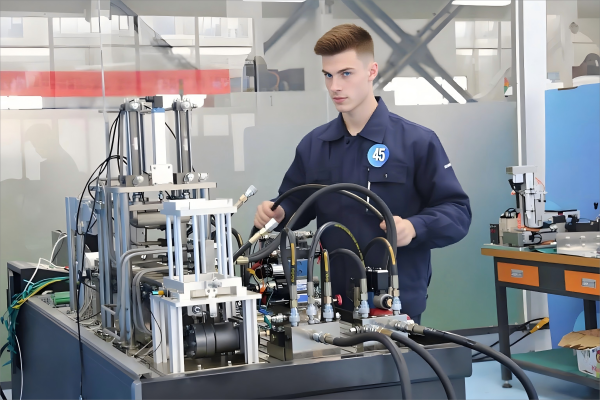

Installation & MaintenanceInstallation, Commissioning, and Maintenance

Hydraulic Services—which specialize in supporting hydraulic systems alongside complementary pneumatic system care—covers the installation, commissioning, operation, and maintenance of hydraulic and pneumatic systems, including best practices for ensuring system reliability and longevity. These services integrate technical expertise to standardize critical operations, ensuring consistent performance across both system types.

Chapter 13

Fault DiagnosisHydraulic System Fault Diagnosis

Provides a systematic approach to identifying and resolving faults in hydraulic systems—specifically addressing Hydraulic failure—including common problems, diagnostic techniques, and repair methods tailored to these failures.

Featured Content

Explore in-depth articles and resources on key topics in hydraulic and pneumatic transmission

Hydraulic Transmission Fundamentals

This comprehensive guide covers the basic principles of hydraulic transmission, from Pascal's Law to system components and operation. It provides a solid foundation for understanding more complex hydraulic systems and applications.

Pneumatic System Design

Learn about the key considerations in designing efficient and reliable pneumatic systems. This article covers component selection, system layout, and optimization techniques for industrial automation applications.

Hydraulic System Components

Power Generation

- Hydraulic Pumps (Gear, Vane, Piston)

- Prime Movers (Electric Motors, Engines)

- Reservoirs and Fluid Storage

Control Components

- Directional Control Valves

- Pressure Control Valves

- Flow Control Valves

Actuators and Accessories

- Hydraulic Cylinders

- Hydraulic Motors

- Filters, Accumulators, and Hoses

Get Your Copy Today

Explore the comprehensive guide to hydraulic and pneumatic transmission systems with expert insights and practical examples.Optical Transceiver.